17-4 PH Stainless Steel Round Bar – Properties, Applications & Suppliers

17-4 PH Stainless Steel Round At Nifty Alloys, we are a trusted 17-4 PH stainless steel round bar supplier in UAE, catering to aerospace, marine, petrochemical, and defense industries with certified and high-quality materials.– Properties, Applications & Suppliers

17-4PH Round Bar: Guide to Properties & Supply

A 17-4PH round bar is a high-strength, corrosion-resistant stainless steel product widely used in demanding industrial applications. It belongs to the precipitation-hardening (PH) family of martensitic stainless steels, which means it can be heat-treated to achieve exceptional mechanical properties. Its unique combination of strength, toughness, and corrosion resistance makes it a superior choice for critical components in industries like aerospace, oil and gas, and marine engineering.

As a leading 17-4PH round bar supplier in UAE at Nifty Alloys LLC, with over a decade of experience sourcing from certified mills, we understand the technical requirements of buyers in the region. This guide provides a detailed overview of 17-4PH stainless steel, covering its properties, common applications, and how to source it effectively in the Middle East. We will explore its chemical composition, mechanical characteristics under various heat treatments, and its performance advantages over other stainless steel grades. Whether you are specifying materials for a new project or sourcing for maintenance, this article will equip you with the essential knowledge about this versatile alloy, available through our extensive stainless steel range.

What is 17-4PH / S17400 Stainless Steel?

17-4PH stainless steel, also identified by its UNS designation S17400 and the designation SAE Type 630, is a chromium-copper precipitation-hardening stainless steel. This martensitic alloy is valued for its ability to achieve very high strength and hardness levels after a relatively simple low-temperature heat treatment. This process minimizes distortion compared to the high-temperature treatments required for other steel alloys, making it ideal for manufacturing complex and precision parts. Its name, "17-4," refers to its approximate composition of 17% chromium and 4% nickel.

Developed in the mid-20th century, 17-4PH was engineered to bridge the gap between the corrosion resistance of austenitic grades like 304 and the high strength of martensitic grades like 410. The result is a material that performs exceptionally well in moderately corrosive environments while withstanding high mechanical stress. Unlike standard austenitic grades, 17-4PH is magnetic. Its balanced properties make it one of the most specified precipitation-hardened stainless steels. For engineers seeking a deeper dive into material grades, our guide on stainless steel grades provides further context.

Feature | 17-4PH (in Condition H1150) | 304 Stainless Steel |

| Type | Martensitic, Precipitation-Hardening | Austenitic |

| Yield Strength | ~115 ksi (795 MPa) | ~30 ksi (205 MPa) |

| Corrosion Resistance | Good, comparable to 304 | Excellent |

| Magnetic? | Yes | No |

| Hardenable? | Yes, by heat treatment | No, by work hardening only |

17-4PH Round Bar chemical composition

TThe chemical composition of a 17-4PH round bar is precisely controlled to deliver its signature blend of strength and corrosion resistance. Its core elements are 15-17.5% chromium for corrosion protection and 3-5% nickel for toughness. However, the key to its precipitation-hardening capability lies in the addition of copper (3-5%) and niobium/columbium (0.15-0.45%).

During heat treatment, these elements form microscopic copper-rich precipitates within the steel's crystal structure. These precipitates obstruct internal dislocation movement, which significantly increases the material's strength and hardness. The niobium further refines the grain structure, enhancing toughness. This unique UNS S17400 chemical composition is what sets it apart from other stainless steels, enabling its high-performance characteristics. Each element plays a critical role in defining the alloy's final mechanical properties and its suitability for specific applications.

Element | Content (%) |

| Carbon (C) | ≤ 0.07 |

| Chromium (Cr) | 15.0 - 17.5 |

| Nickel (Ni) | 3.0 - 5.0 |

| Copper (Cu) | 3.0 - 5.0 |

| Manganese (Mn) | ≤ 1.00 |

| Silicon (Si) | ≤ 1.00 |

| Niobium (Nb) + Tantalum (Ta) | 0.15 - 0.45 |

| Iron (Fe) | Balance |

17-4 PH Material Equivalent

| Standard system | Designation |

|---|---|

| UNS | S17400 |

| AISI / SAE | 630 |

| EN / DIN | 1.4542 |

| EN name | X5CrNiCuNb16‑4 |

| JIS | SUS630 |

| Common name | 17‑4PH, Type 630 |

Mechanical Properties & Heat Treatments

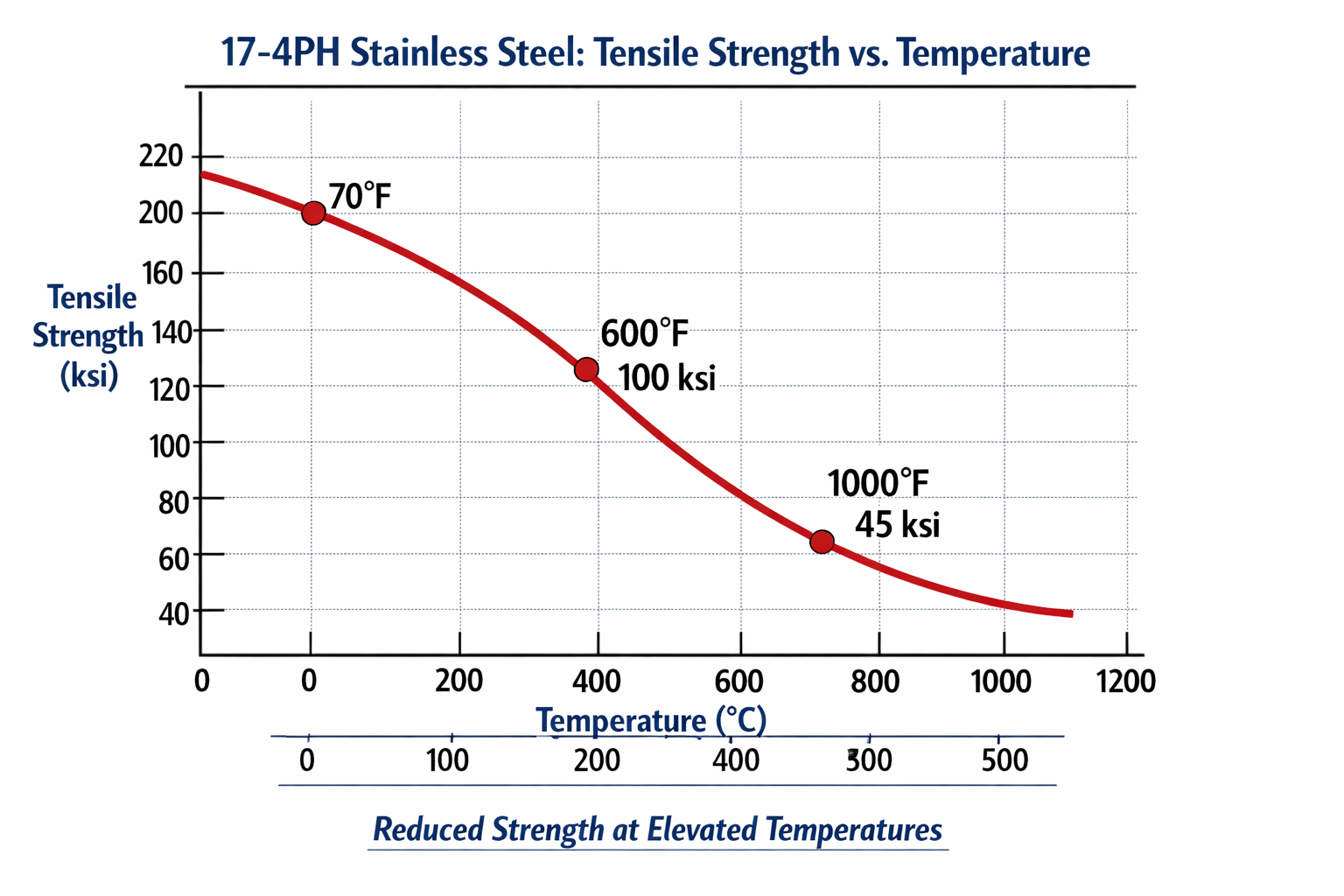

The mechanical properties of 17-4PH stainless steel are highly versatile and can be tailored through various heat treatments. The material is typically supplied in the solution-annealed state (Condition A), which is its softest and most machinable form. From there, it undergoes a single-step aging (hardening) treatment at a specific temperature to achieve the desired balance of strength, hardness, and toughness.

The most common conditions include H900, H1025, H1075, and H1150. The "H" designates the aging temperature in Fahrenheit. For example, H900 is aged at 900°F (482°C), which produces the highest strength but lowest toughness. Conversely, the 17-4PH stainless steel properties H1150 are achieved by aging at 1150°F (621°C), resulting in lower strength but excellent toughness, ductility, and stress corrosion cracking resistance. This process of over-aging is particularly beneficial for components in harsh marine or sour gas environments. The ability to customize these properties makes 17-4PH an incredibly adaptable material for high-performance applications, such as those in aerospace engineering where strength-to-weight ratio is critical.

Condition | Tensile Strength (UTS), min. | Yield Strength (0.2% OS), min. | Elongation (% in 2"), min. | Hardness, Rockwell C (HRC) |

| A (Annealed) | - | - | - | ~38 HRC |

| H900 | 190 ksi / 1310 MPa | 170 ksi / 1170 MPa | 10 | ~44 HRC |

| H1025 | 155 ksi / 1070 MPa | 145 ksi / 1000 MPa | 12 | ~38 HRC |

| H1075 | 145 ksi / 1000 MPa | 125 ksi / 860 MPa | 13 | ~36 HRC |

| H1150 | 135 ksi / 930 MPa | 105 ksi / 725 MPa | 16 | ~33 HRC |

| H1150-M | 115 ksi / 795 MPa | 75 ksi / 520 MPa | 18 | ~28 HRC |

| H1150-D | 125 ksi / 860 MPa | 105 ksi / 725 MPa | 14 | ~30 HRC |

Key Properties: Strength, Corrosion Resistance & Machinability

The widespread adoption of martensitic 17-4PH steel stems from its well-rounded performance profile. Engineers and procurement managers select this alloy for its three primary advantages: high strength, good corrosion resistance, and fair machinability.

- Exceptional Strength: After heat treatment, 17-4PH can achieve a yield strength of up to 170 ksi (1170 MPa) in the H900 condition. This is significantly higher than common austenitic grades like 304 or 316, making it suitable for load-bearing components where size and weight are constraints.

- Reliable Corrosion Resistance: The general corrosion resistance of 17-4PH is comparable to that of 304 stainless steel in most media. It performs well in atmospheric conditions and in dilute acids and salts found in marine and petrochemical environments. For maximum resistance to stress corrosion cracking (SCC), aging at 1025°F (552°C) or higher is recommended, with the H1150 condition offering optimal protection.

- Good Machinability: In its annealed (Condition A) state, 17-4PH offers good machinability, similar to that of 304 stainless steel. After hardening, machining becomes more challenging due to the increased hardness. Therefore, most fabrication is completed before the final aging treatment.

- Magnetic Properties: As a martensitic steel, 17-4PH is ferromagnetic in all conditions. This property can be useful for applications requiring magnetic response, such as sensors or actuators, but should be considered if magnetism is undesirable.

Property | 17-4PH (H1150) | 304 Stainless Steel | 410 Stainless Steel |

| Yield Strength (min.) | 105 ksi | 30 ksi | 90 ksi (Hardened) |

| General Corrosion | Good | Excellent | Fair |

| SCC Resistance | Excellent (Overaged) | Very Good | Poor |

| Magnetic? | Yes | No | Yes |

Applications & Industries for S17400 Round Bars

The unique combination of high strength, toughness, and corrosion resistance makes S17400 round bar a first-choice material for critical components across several demanding industries. Its ability to be precision-machined in a softer state and then hardened with minimal distortion is a key advantage.

Common applications include:

- Aerospace: Landing gear components, structural airframe sections, engine parts, and high-pressure hydraulic fittings where strength-to-weight ratio and reliability are paramount.

- Oil & Gas: The use of S17400 round bar applications oil gas is extensive. It is specified for downhole tools, valve stems, pump shafts, and wellhead components, especially where resistance to sulfide stress cracking is required. In the UAE, for example, ADNOC projects often specify 17-4PH in the H1150 condition for components exposed to moderately corrosive production fluids, valuing its proven performance and reliability in demanding service environments.

- Marine: Propeller shafts, pump components, and offshore platform hardware benefit from its good corrosion resistance in seawater, particularly when compared to standard martensitic steels. Its high strength is ideal for withstanding the immense mechanical stresses of marine propulsion systems.

- Power Generation: Used for turbine blades, fasteners, and other high-stress parts in nuclear and conventional power plants. Its consistent performance at moderately elevated temperatures is a key factor in its selection.

- General Manufacturing: Found in high-performance applications such as food processing equipment, chemical processing machinery, plastic injection molds, and high-strength fasteners.

At Nifty Alloys, we supply 17-4PH round bar and other forms like 17-4PH sheets to support these critical sectors. Explore our full range of 17-4PH stainless steel products.

17-4PH Round Bar Supplier in UAE, Saudi Arabia & Oman

As a premier 17-4PH S17400 supplier UAE, Nifty Alloys LLC is strategically positioned to serve the high-stakes industries of the Middle East. We maintain a comprehensive stock of 17-4PH round bar in diameters ranging from 10mm to 300mm, primarily in the H1150 condition to meet the rigorous demands of the oil and gas and marine sectors. Every bar we supply is fully traceable and accompanied by mill test certificates (MTC) to EN 10204 3.1, ensuring compliance with international standards.

Our supply chain is optimized for rapid delivery across the UAE, Saudi Arabia, and Oman, minimizing project downtime. Unlike brokers who face long lead times, our local stockholding enables us to fulfill urgent requirements promptly. We offer competitive pricing by sourcing directly from globally recognized and certified mills. Our commitment extends beyond supply; we provide value-added services such as cutting to length and technical support to ensure you receive a material solution that is fit-for-purpose and cost-effective. Partner with us for reliable, standards-compliant material supply. Contact us via our request form for immediate assistance.

Available Sizes & Standards | Details |

| Diameter Range | 10 mm to 300 mm |

| Common Condition | H1150 (Double Aged) |

| Primary Standard | ASTM A564 / ASME SA564 |

| Aerospace Standard | AMS 5643 |

| Certifications | Mill Test Certificates to EN 10204 3.1 |

Buying Guide: Sizes, Standards & Pricing 2025

When procuring 17-4PH round bar, several factors influence selection and cost. The most critical considerations are the required diameter, length, and specified heat treatment condition, as these directly impact mechanical properties and price. Most suppliers, including Nifty Alloys, stock material compliant with ASTM A564, the primary standard for hot-rolled and cold-finished precipitation-hardening steel bars.

Pricing in 2025 is influenced by global nickel and copper market fluctuations, as well as logistical costs. Key factors affecting your final price include:

- Heat Treatment Condition: H900 is often more expensive due to processing, while the widely available H1150 condition may offer a more economical solution.

- Quantity: Volume discounts are standard practice for larger project orders.

- Certifications: Requirements for additional testing or non-standard certifications will add to the cost.

- Supplier Stock: Sourcing from a local stockholder in the UAE can reduce shipping costs and lead times compared to overseas mill orders.

Specification | Common Range |

| Standard Diameters | 10 mm to 300 mm |

| Standard Lengths | 3 to 6 meters |

| Governing Standard | ASTM A564 / ASME SA564 |

| Tolerance | As per ASTM A484 |

Frequently Asked Questions (FAQ)

1. Where can I buy 17-4PH stainless steel round bar in the UAE?

You can buy 17-4PH stainless steel round bars from Nifty Alloys LLC, a UAE stockist supplying certified grades with nationwide delivery.

2. Where can I find certified 17-4PH stainless steel round bar distributors in the UAE?

Certified 17-4PH round bars with EN10204 3.1 MTCs are available from Nifty Alloys LLC and approved industrial steel distributors in the UAE.

3. Which companies offer custom cutting services for 17-4PH stainless steel round bars?

Nifty Alloys LLC provides custom cutting and size-based supply of 17-4PH stainless steel round bars for project-specific needs.

4. What delivery options are available for 17-4PH stainless steel round bars in the UAE?

Delivery options include same-day dispatch, scheduled site delivery, and bulk transport across Dubai, Abu Dhabi, Sharjah, and other Emirates.

5. Who are the best suppliers of 17-4PH stainless steel round bars near me?

Nifty Alloys LLC is a trusted UAE supplier known for stock availability, certification, and reliable logistics.

6. Which brands of 17-4PH stainless steel round bars are available in the UAE?

Common international brands include Outokumpu, Sandvik, Böhler, Voestalpine, and Nippon Steel, depending on availability.

7. How do 17-4PH stainless steel round bar brands in the UAE compare?

Brands differ mainly in heat treatment consistency, surface finish, tolerance control, and certification quality, while chemical composition remains standard.

8. What are the price ranges for 17-4PH stainless steel round bars in Dubai?

Prices vary by diameter, heat treatment, and quantity. Contact Nifty Alloys LLC for current per-kg or per-length pricing.

9. What factors affect the price of 17-4PH stainless steel round bars in the UAE?

Key factors include bar diameter, length, condition (H900–H1150), certification, brand, and order volume.

10. What are the technical specifications of 17-4PH stainless steel round bars?

17-4PH (UNS S17400) offers high strength, corrosion resistance, and precipitation hardening, with tensile strength up to ~1310 MPa (H900).

11. How can I identify high-quality 17-4PH stainless steel round bars?

Check for EN10204 3.1 certification, clear heat numbers, correct hardness condition, and reputable supplier documentation.

12. What certifications should 17-4PH stainless steel round bars have in the UAE market?

They should include EN10204 3.1 MTCs, chemical and mechanical test reports, and compliance with ASTM A564 / AMS standards.

Conclusion

In summary, the 17-4PH round bar stands out as a high-performance material engineered for the most challenging industrial environments. Its unmatched combination of high strength, good corrosion resistance, and adaptability through heat treatment makes it an indispensable alloy for aerospace, oil and gas, marine, and power generation sectors. Understanding its properties, particularly in conditions like H1150, is critical for ensuring component reliability and longevity.

For procurement professionals in the UAE, Saudi Arabia, and Oman, securing a reliable supply of certified material is paramount. At Nifty Alloys, we are committed to providing high-quality, traceable 17-4PH stainless steel that meets stringent international standards. Request a 17-4PH quote from Nifty Alloys UAE today via our contact page to ensure your project is built with materials you can trust.

This article provides a comprehensive overview of 4140 alloy steel, detailing its composition, prope...

In this comprehensive guide, we break down exactly what is alloy steel, the different types of alloy...

This comprehensive guide explores the leading alloy steel suppliers in the UAE, emphasizing their re...

EN19 / 42CrMo4 Alloy Steel is a high tensile chromium-molybdenum steel known for its excellent stren...

Elevate Your Projects with

with

Our Superior Steels

Our Superior Steels