31CrMoV9 Steel Steel Supplier in UAE: Properties, Applications, and Supply – Nifty Alloys LLC

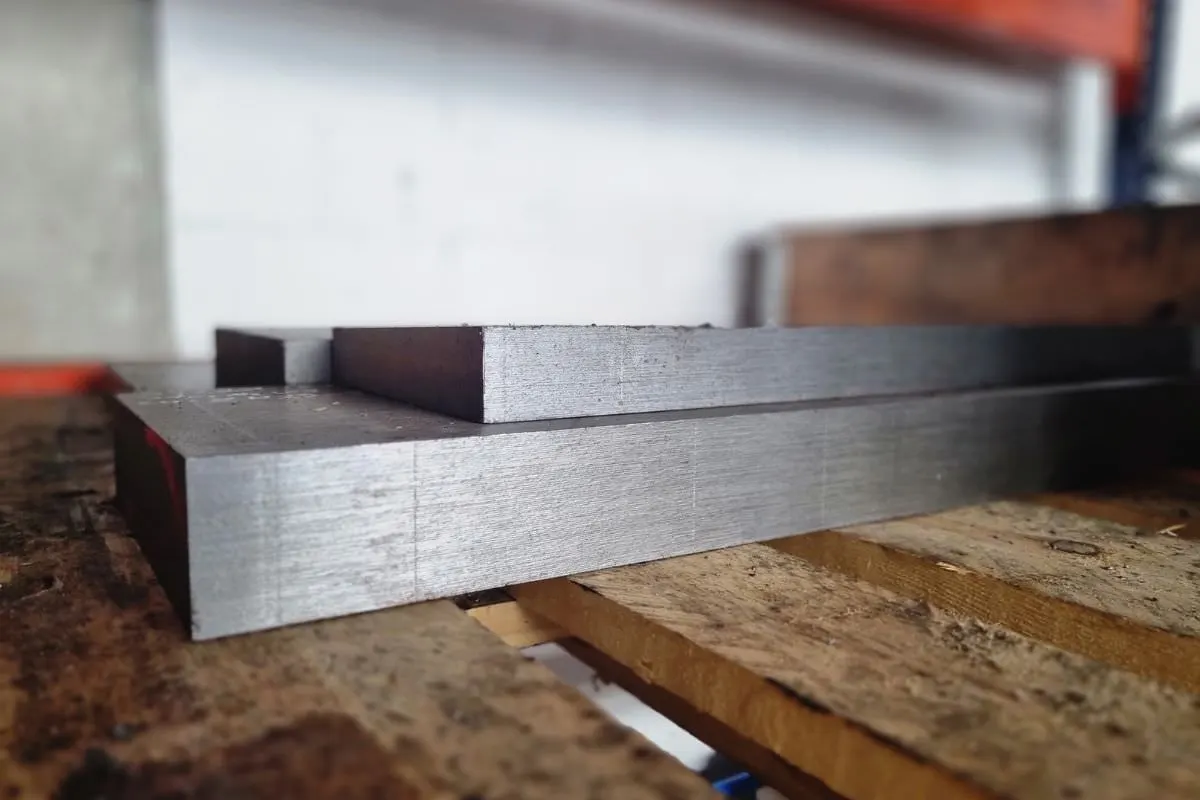

Nifty Alloys LLC is a trusted stockist and supplier of 31CrMoV9 steel in the UAE, providing high-quality, certified materials for critical engineering and industrial applications. This chromium-molybdenum-vanadium alloy steel is engineered for superior performance in demanding environments. It offers an exceptional combination of high tensile strength, toughness, and creep resistance at elevated temperatures, making it a preferred material for heavy-duty components.

As a leading supplier, we ensure our clients receive 31CrMoV9 material that meets stringent international standards. Our extensive inventory and advanced sourcing capabilities allow us to deliver reliable solutions for projects across the oil and gas, power generation, and manufacturing sectors. We are committed to supplying materials that provide durability and performance where it matters most.

Key Features & Benefits

31CrMoV9 steel offers a superior combination of mechanical properties and durability, making it highly suitable for demanding engineering environments. Key features and benefits include:

- High Tensile Strength: Delivers robust performance in high-stress and load-bearing applications.

- Excellent Toughness: Maintains integrity under dynamic and impact loading.

- Outstanding Wear Resistance: Prolongs service life in friction-intense and abrasive conditions.

- Superior Heat Resistance: Retains mechanical performance at elevated temperatures, ensuring dimensional stability.

- Good Hardenability: Responds effectively to heat treatment, allowing for tailored properties such as increased strength and improved machinability.

- Versatility: Suitable for a broad range of applications, including automotive, power generation, and heavy industry components.

- Reliable Performance: Meets rigorous international standards for safety and quality assurance.

31CrMoV9 steel Applications and Uses

Chemical Composition of 31CrMoV9 Steel

31CrMoV9 steel Forging

31CrMoV9 steel Normalising

Equivalent Grades of 31CrMoV9 Steel

31CrMoV9 steel Hardening

31CrMoV9 steel Heat Treatment

Mechanical Properties

31CrMoV9 steel Supply Forms

Elevate Your Projects with

with

Our Superior Steels

Our Superior Steels

Looking for a 31CrMoV9 Steel Supplier in UAE? Nifty Alloys LLC offers a complete range of alloy steel bars, rods, and forgings for industrial applications. As a trusted material stockist, we ensure competitive prices, quick dispatch, and material traceability for every order. Contact us today to learn more about our 31CrMoV9 Alloy Steel stock availability, sizes, and pricing options.