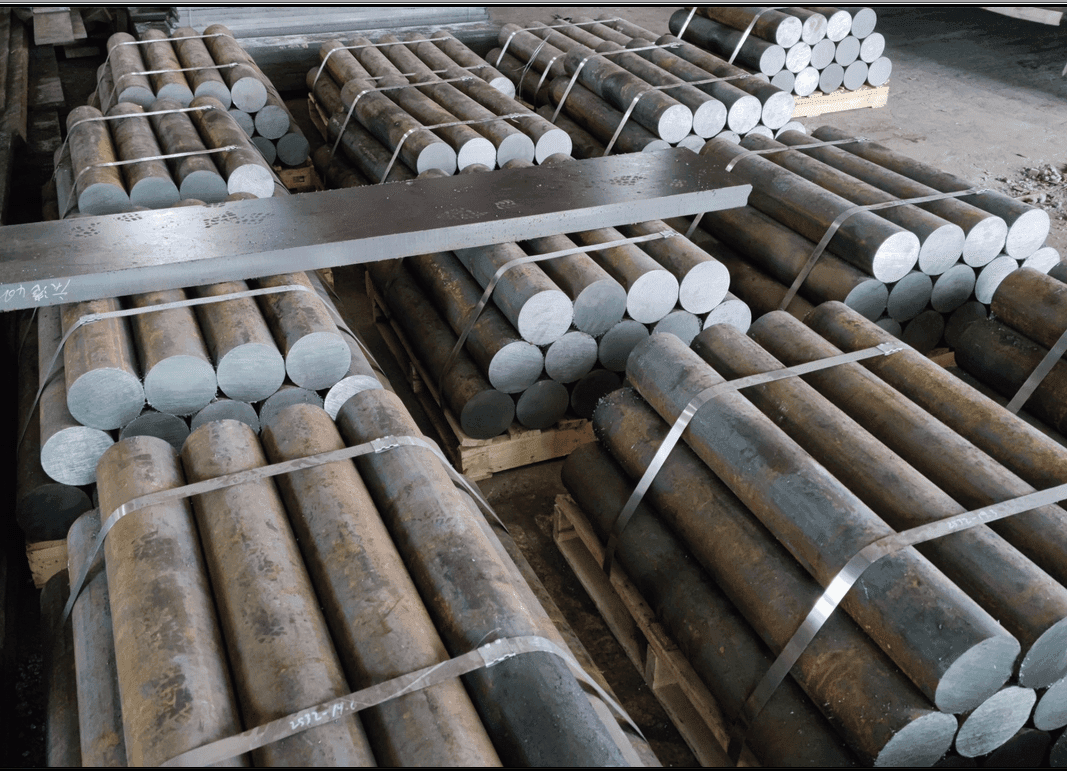

Nifty Alloys LLC is a trusted supplier and stockist of 655M13 Case-Hardening Steel based in the UAE, serving industries across the Middle East and exporting globally. 655M13 steel is a nickel-chromium-molybdenum alloy steel known for its exceptional wear resistance, core strength, and ability to be case-hardened for high-stress engineering applications.

When you need reliable performance under pressure, 655M13 delivers both a tough interior and a hard, wear-resistant surface—making it ideal for gears, shafts, and heavy-duty components.

What Is 655M13 Case-Hardening Steel?

655M13 (equivalent to AISI 9310 or EN 17NiCrMo6-4) is a low-carbon, nickel-chromium-molybdenum steel developed specifically for carburizing (case hardening) applications. It offers a strong, ductile core combined with a highly hardenable surface, providing the perfect balance between toughness and wear resistance.

Once case-hardened, 655M13 achieves a surface hardness of up to 60 HRC, making it suitable for critical moving parts that require long service life under load.

Applications of 655M13 Steel

Chemical Composition of 655M13 Steel

Carburising / Case Hardening

Softening of 655M13 Steel

Heat Treatment of 655M13 Steel

Equivalent Grades of 655M13 Steel

Elevate Your Projects with

with

Our Superior Steels

Our Superior Steels

Nifty Alloys LLC is a reliable supplier and stockist of 655M13 Case Hardening Steel based in the United Arab Emirates, serving customers across the Middle East, Europe, Asia, and Africa. We supply 655M13 low-carbon alloy steel designed for case hardening applications, offering a tough, shock-resistant core with a hard, wear-resistant surface after heat treatment. This grade is widely used for gears, pinions, shafts, camshafts, and automotive transmission components where surface durability and core toughness are critical. For buyers seeking a trusted 655M13 case hardening steel supplier in the UAE or a dependable source of case hardening alloy steel for export, Nifty Alloys LLC provides consistent quality, material traceability, and reliable supply.