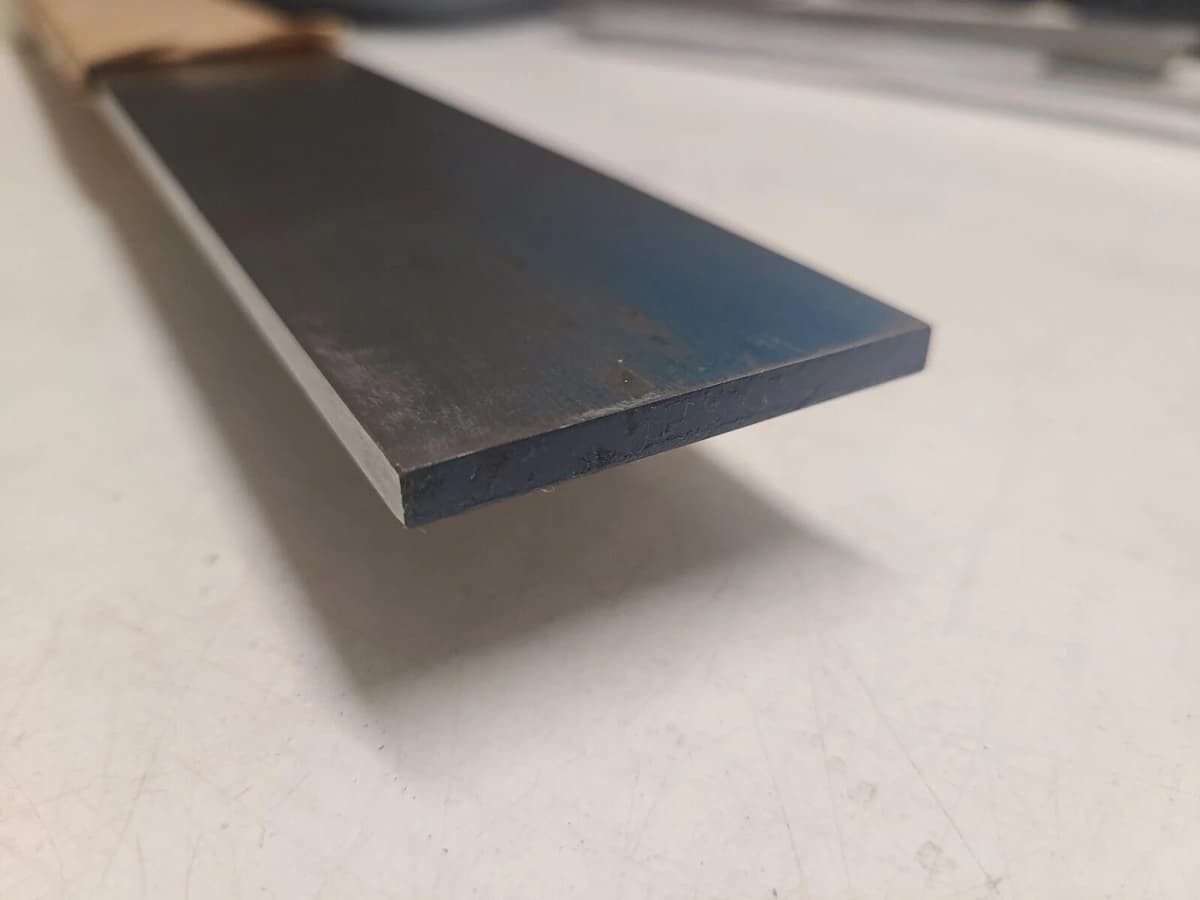

D2 tool steel is a high-carbon, high-chromium, air-hardening cold work tool steel renowned for its exceptional performance in demanding industrial applications. It offers a superior combination of high wear resistance, excellent hardness, and good dimensional stability after heat treatment. Its robust properties make it an essential material for producing high-performance cutting tools, dies, and punches where longevity and precision are critical. For engineers and manufacturers, D2 steel provides a reliable solution for tooling that must withstand significant abrasion and compressive forces.

Nifty Alloys LLC is a premier stockist and supplier of high-quality D2 tool steel bars, plates, and blocks, serving clients across the UAE and worldwide. Our materials meet rigorous international standards, ensuring your operations benefit from consistent performance and reliability.

What is D2 Tool Steel?

D2 tool steel is a versatile and widely used grade in the cold-work category of tool steels, classified under the AISI (American Iron and Steel Institute) system. Its defining characteristic is a high concentration of carbon (approximately 1.5%) and chromium (approximately 12%). This specific chemical balance results in a microstructure rich in large, hard chromium carbides, which are the source of its outstanding wear resistance.

Unlike many other tool steels that require rapid quenching in oil or water, D2 is an air-hardening steel. This means it hardens effectively with a slower cooling rate in air, which significantly minimizes distortion and the risk of cracking during the heat treatment process. This feature ensures exceptional dimensional stability, making it ideal for creating complex or large tools where tight tolerances must be maintained. You can rely on D2 for its superior compressive strength and edge retention, which are crucial for long production runs in stamping, forming, and cutting operations.

Industrial Applications of D2 Tool Steel

D2 Tool Steel Chemical Composition

Machinability and Fabrication

Heat Treatment Process for D2 Tool Steel

D2 Tool Steel Equivalent Grades

Mechanical Properties of D2 Tool Steel

Key Properties of D2 Tool Steel

D2 vs. D3 Tool Steel: A Quick Comparison

D2 Tool Steel Price and Availability

Elevate Your Projects with

with

Our Superior Steels

Our Superior Steels

Nifty Alloys LLC is a trusted supplier and stockist of D2 Tool Steel based in the United Arab Emirates, serving customers across the Middle East, Europe, Asia, and Africa. We supply high-quality D2 high-carbon, high-chromium tool steel, known for its excellent wear resistance, high hardness, and good dimensional stability after heat treatment. D2 tool steel is widely used in dies, punches, shear blades, slitting knives, forming tools, and precision tooling components where long service life and abrasion resistance are critical. For buyers seeking a reliable D2 tool steel supplier in the UAE or a dependable source of D2 tool steel for export, Nifty Alloys LLC offers consistent quality, full material traceability, and dependable supply.