Tool Steel International Standards: A Comprehensive Guide

Tool steel is the foundation of modern manufacturing, enabling the creation of everything from precision machine components to heavy-duty industrial dies. These specialized alloys are engineered for exceptional hardness, wear resistance, and toughness under extreme conditions. For industries that rely on high-performance tooling—including machining, die-making, and engineering—the quality and reliability of these materials are non-negotiable. This is where international standards become critical, providing a universal language for quality, performance, and interchangeability.

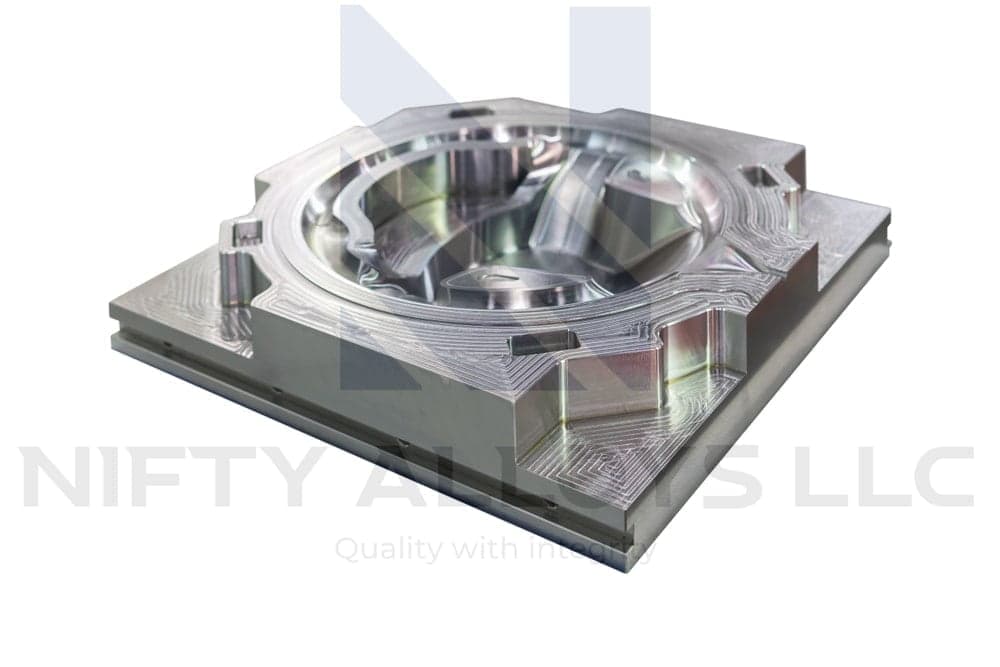

Standards ensure that a specific grade of tool steel, whether sourced in Europe, Asia, or the Americas, meets defined criteria for composition and performance. This global framework eliminates ambiguity and guarantees that you receive materials that function as expected. As a global stockist of certified tool steel materials, Nifty Alloys LLC is committed to supplying standard-compliant grades to industries worldwide, ensuring your operations are built on a foundation of proven quality.

What Are Tool Steel International Standards?

Tool steel international standards are a set of technical documents that define the precise requirements for the manufacturing, testing, and certification of various tool steel grades. These standards are developed by national and international organizations to create uniformity across the global supply chain. When you procure tool steel compliant with these standards, you are assured that it meets specific benchmarks for:

- Chemical Composition: Exact limits for elements like carbon, chromium, molybdenum, and vanadium, which determine the steel's core properties.

- Mechanical Properties: Minimum requirements for hardness, tensile strength, yield strength, and impact toughness after specified heat treatment.

- Heat Treatment Guidelines: Detailed procedures for annealing, hardening, quenching, and tempering to achieve the desired material characteristics.

- Hardness and Toughness Criteria: Specific Rockwell (HRC) or Brinell (HB) hardness ranges that a grade must achieve.

- Dimensional Tolerances: Permissible variations in the size and shape of bars, plates, and blocks.

By adhering to these globally recognized standards, manufacturers, suppliers, and end-users can communicate technical requirements clearly and confidently.

Major Tool Steel Standard Organizations

Tool Steel Categories and Their Governing Standards

Chemical Composition Requirements

Mechanical Properties According to Standards

Heat Treatment Requirements

Tool Steel Equivalent Grades

Applications by Standard

Forms Available at Nifty Alloys LLC

Certifications & Compliance Provided

Elevate Your Projects with

with

Our Superior Steels

Our Superior Steels

Tool steel international standards ensure consistent quality, reliable performance, and global compatibility across manufacturing, machining, and tooling applications. Whether you're comparing ASTM, DIN, EN, ISO, AISI, or JIS classifications, these standards define the chemical composition, mechanical properties, and heat-treatment requirements that determine tool steel performance. Nifty Alloys LLC supplies certified tool steel grades compliant with major global standards, offering ready stock, competitive pricing, and fast worldwide delivery.