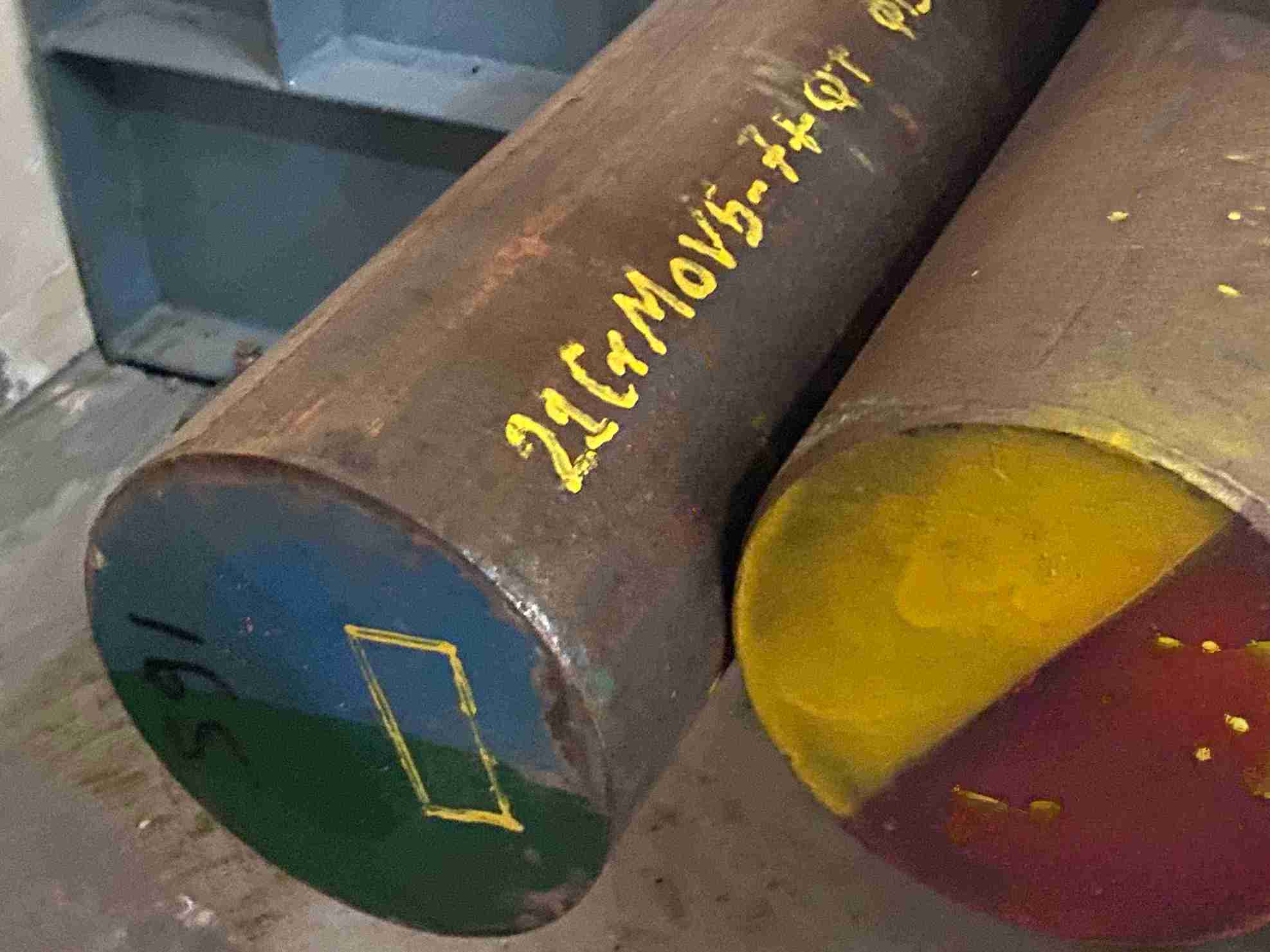

1.7709 / 21CrMoV5-7 Steel – Complete Guide: Composition, Properties, Applications & Datasheet

In the critical infrastructure of power generation and chemical processing, material failure is not an option. 1.7709 steel, chemically designated as 21CrMoV5-7 material, stands as a benchmark for creep-resistant engineering steels used in high-temperature environments. This low-alloy steel is specifically engineered to retain structural integrity under continuous stress at temperatures up to 550°C.

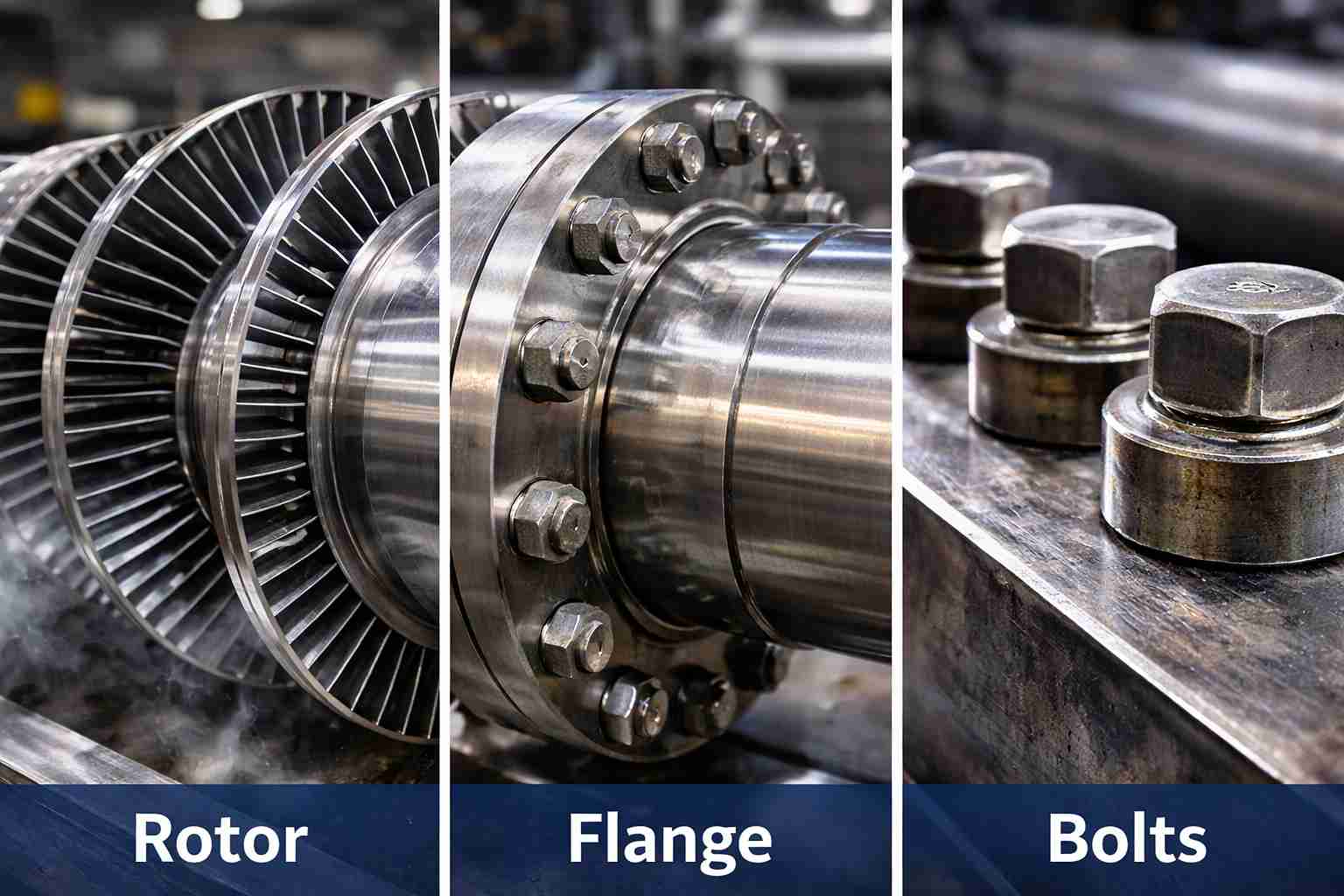

For procurement engineers and metallurgists, selecting 1.7709 ensures a balance of high yield strength and exceptional toughness. It serves as the material of choice for components subjected to extreme thermal cycling, such as turbine rotors and high-pressure fasteners. As a leading supplier, Nifty Alloys LLC provides this comprehensive guide to help you understand the technical nuances of this grade. Whether you are sourcing raw stock or finished forgings, understanding the specific capabilities of high-temperature alloys is essential for operational safety and longevity.

What Is 21CrMoV5-7 Steel?

21CrMoV5-7 material (Werkstoff number 1.7709) is a pearlitic-martensitic creep-resisting steel. It is defined primarily by its chromium, molybdenum, and vanadium alloying elements, which work in concert to provide resistance to hydrogen attack and high-temperature creep. Unlike standard structural steels that lose significant strength above 300°C, 1.7709 maintains its yield strength and ductility well into the 500°C–550°C range.

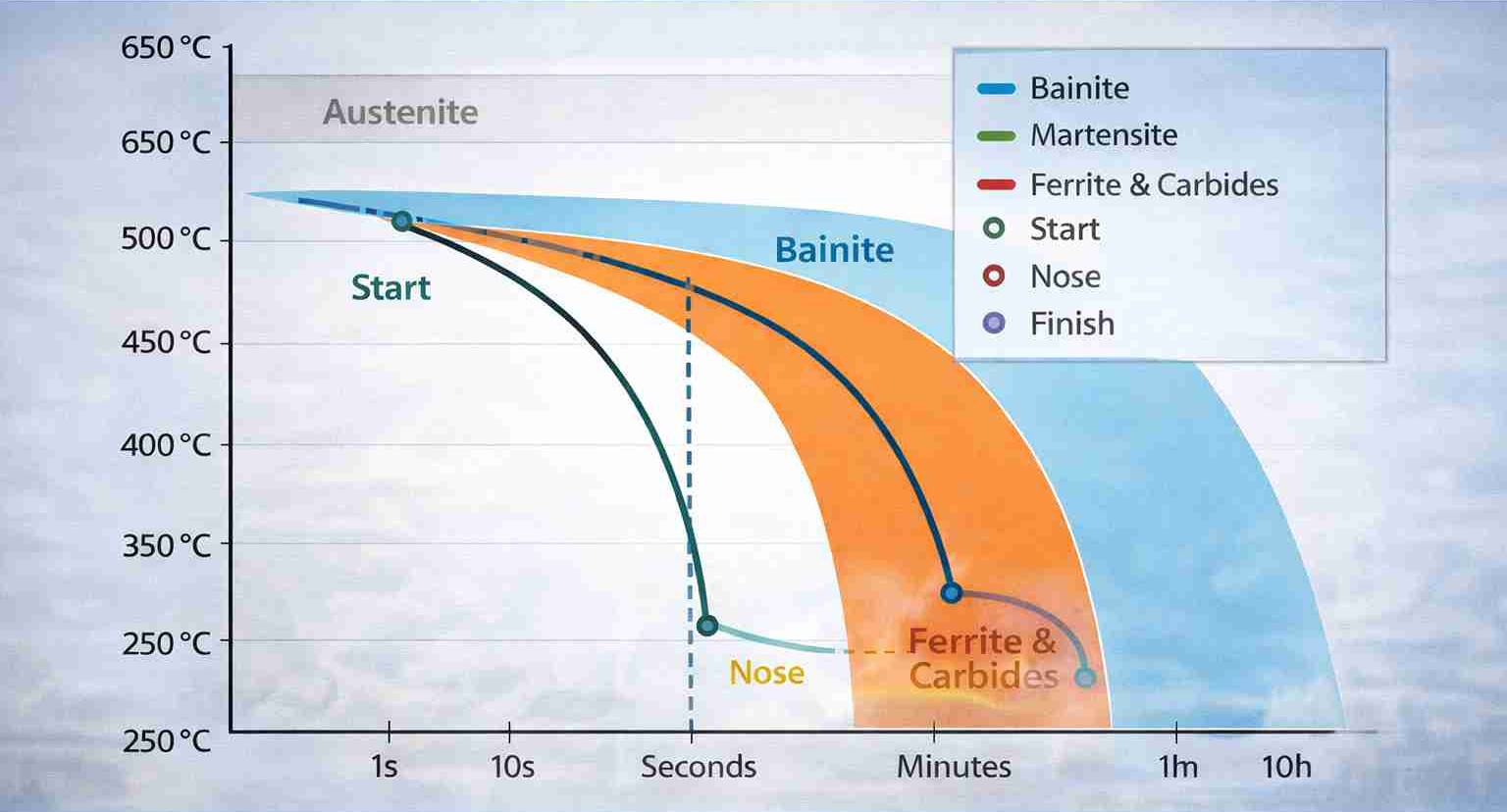

The material is standardized under EN 10269, which covers steels and nickel alloys for fasteners with specified elevated and/or low-temperature properties. The microstructure, typically tempered martensite or bainite depending on the heat treatment and section thickness, ensures uniform hardness across large cross-sections. This hardenability is a critical feature, allowing the manufacturing of massive components like turbine shafts without sacrificing core strength. Its classification as a heat-treatable steel means its final mechanical properties can be precisely tailored through normalizing, quenching, and tempering processes to meet specific project requirements (SEP 10204 3.1 certification is standard).

Chemical Composition

The 21CrMoV5-7 chemical composition is strictly controlled to ensure the formation of stable carbides, which are essential for creep resistance. The interaction between Vanadium (V) and Carbon (C) precipitates fine carbides that pin grain boundaries, preventing slip at elevated temperatures. Molybdenum (Mo) contributes significantly to solid solution strengthening and reduces the risk of temper embrittlement.

Below is the standard composition range based on EN 10269:

Element | Min % | Max % | Description of Role |

| Carbon (C) | 0.20 | 0.25 | Provides base hardness and strength; forms carbides with Cr, Mo, and V. |

| Silicon (Si) | 0.15 | 0.40 | Acts as a deoxidizer during steelmaking; improves oxidation resistance. |

| Manganese (Mn) | 0.40 | 0.70 | Improves hardenability and tensile strength; combines with sulfur to improve machinability. |

| Chromium (Cr) | 2.40 | 2.80 | Primary element for oxidation resistance and hardenability; forms stable Cr-carbides. |

| Molybdenum (Mo) | 0.90 | 1.10 | Increases high-temperature strength and creep resistance; inhibits pitting. |

| Vanadium (V) | 0.25 | 0.35 | Refines grain structure; forms hard V-carbides for secondary hardening. |

| Phosphorus (P) | - | 0.020 | Kept low to prevent brittleness and improve impact toughness. |

| Sulfur (S) | - | 0.015 | Restricted to maximize ductility and transverse impact properties. |

Note: Precise control of trace elements like P and S is vital for applications requiring high impact energy values at low temperatures.

Mechanical Properties

The mechanical performance of 1.7709 steel is characterized by high tensile strength combined with good ductility. However, the most defining characteristic is its retention of these properties at service temperatures. The data below represents typical values for material in the quenched and tempered (QT) condition at room temperature.

Property | Value | Unit |

| Tensile Strength (Rm) | 850 - 1000 | MPa |

| Yield Strength (Rp0.2) | ≥ 650 | MPa |

| Elongation (A5) | ≥ 15 | % |

| Reduction of Area (Z) | ≥ 45 | % |

| Impact Energy (ISO-V) | ≥ 40 | J (at 20°C) |

| Hardness | 260 - 320 | HB (Brinell) |

High-Temperature Yield Strength:

Engineers must note that while room temperature yield is ≥650 MPa, at 500°C, the 0.2% proof stress typically remains above 450 MPa. This retention is what qualifies 1.7709 for critical rotating machinery. Achieving these properties requires strict adherence to heat treatment protocols to ensure the carbide precipitation is uniform throughout the steel matrix.

Heat Treatment Guide

Proper heat treatment is non-negotiable for 21CrMoV5-7 material. The goal is to achieve a fully bainitic or tempered martensitic structure that offers the best compromise between creep strength and toughness. Improper heat treatment can lead to coarse grain structures, significantly reducing the lifespan of the component.

Process Parameters:

- Normalizing (940-970°C):

The steel is heated to the austenitizing range to dissolve carbides and homogenize the structure. It is then air-cooled. This step refines the grain structure, preparing it for hardening. - Quenching / Hardening (880-920°C):

Re-heating to the hardening temperature followed by quenching, typically in oil. Oil quenching is preferred over water to minimize the risk of distortion or quench cracking, given the steel's high hardenability. - Tempering (680-740°C):

This is the most critical step. Tempering at this high range allows for the precipitation of secondary carbides (Vanadium carbides). This "secondary hardening" phenomenon is what gives 1.7709 its superior creep resistance. The holding time should be sufficient (usually 2+ hours) to ensure structural stability. Air cooling follows tempering.

Stress Relieving: For heavily machined components, stress relieving at 50°C below the tempering temperature is recommended to maintain dimensional stability.

1.7709 Equivalent Grades

1.7709 equivalent grades are vital for global procurement strategies. While direct equivalents are rare due to specific Vanadium content variations, several international standards offer grades with overlapping chemistry and performance characteristics suitable for similar applications.

Standard | Grade / Designation | Link |

| ASTM (USA) | A 193 Grade B16 / F22V | View ASTM F22V |

| BS (UK) | 622 Gr.515 | View BS 622 |

| JIS (Japan) | SCMV 5 | View JIS SCMV5 |

| AFNOR (France) | 20 CDV 5.07 | - |

| UNI (Italy) | 20 CrMoV 5 7 | - |

Note: While these grades are functionally similar, always verify specific datasheet parameters (especially V content) before substitution.

Applications

The application spectrum of 1.7709 is defined by high pressure, high temperature, and high stress. It is a staple material in the energy sector.

- Steam Turbine Rotors: The primary application. The steel's hardenability allows for uniform properties even in large diameter forgings used for turbine shafts and disks.

- High-Temperature Fasteners: Used extensively for bolts, studs, and nuts in turbine casings and steam lines. The resistance to relaxation is key here; bolts must maintain clamping force despite years of thermal expansion cycles.

- Pressure Vessels: Forged flanges, valve bodies, and breeches in chemical reactors operating at elevated temperatures.

- Hydrogen Service: The chromium and molybdenum content provides excellent resistance to hydrogen embrittlement, making it suitable for hydrogenation plants.

We supply these materials as raw stock or rough-machined power forgings tailored to your dimensional requirements.

Machining & Welding

Machining:

1.7709 is generally machined in the annealed or quenched and tempered condition. In the QT condition (approx. 300 HB), it presents moderate difficulty. Using carbide tools with rigid setups is recommended to manage cutting forces.

- Cutting Speed: Moderate speeds (90-120 m/min) with adequate coolant.

- Surface Finish: excellent surface finishes are achievable, which is critical for fatigue resistance in rotating parts.

Welding:

Welding 21CrMoV5-7 requires expertise. Due to its high alloy content, it has a high carbon equivalent, making it susceptible to cold cracking.

- Pre-heating: Essential. Pre-heat to 300-350°C before welding to slow the cooling rate.

- Consumables: Use matching filler metals (Cr-Mo-V types) to ensure the weld zone matches the base metal's creep properties.

- PWHT: Post-Weld Heat Treatment is mandatory. The weldment must be stress-relieved or re-tempered (680-720°C) immediately after welding to reduce residual stresses and temper the martensite formed in the Heat Affected Zone (HAZ).

Datasheet Summary

Below is a consolidated summary of the 21CrMoV5-7 datasheet. This quick-reference data aids in rapid material verification.

- Material Number: 1.7709

- Density: 7.85 g/cm³

- Modulus of Elasticity: 210 GPa (at 20°C)

- Thermal Conductivity: 33 W/(m·K)

- Thermal Expansion: 12.7 x 10⁻⁶ K⁻¹ (20-400°C)

- Creep Rupture Strength (100,000h at 500°C): Approx 180 MPa

Why Nifty Alloys?

At Nifty Alloys LLC, we understand that supply chain reliability is as critical as material quality. We specialize in sourcing and stocking high-performance alloys for the UAE and Middle East markets.

- Strategic Stock: Our Sharjah warehouse holds ready stock of 1.7709 rounds and billets, minimizing lead times for urgent maintenance shutdowns.

- Certified Quality: Every item is supplied with EN 10204 3.1 certifications from reputable mills, ensuring full traceability and compliance with EN and ASTM standards.

- Technical Partnership: Our commitment goes beyond supply. We partner with clients to provide technical documentation, third-party inspection coordination, and value-added services like cutting and rough machining.

When your project demands precision, Nifty Alloys delivers.

FAQ

1. What is 21CrMoV5-7 used for?

It is primarily used for components requiring high creep resistance and tensile strength at temperatures up to 550°C. Common applications include steam turbine rotors, shafts, turbine blades, high-temperature fasteners (bolts/studs), and flanges for pressure vessels in power generation and petrochemical industries.

2. What are the key 1.7709 properties?

The 1.7709 steel grade offers excellent high-temperature yield strength, good hardenability for large cross-sections, and resistance to hydrogen attack. Its specific benefit is the stability of its microstructure over long durations of thermal stress (creep resistance).

3. What are the equivalent grades for 1.7709?

While exact matches vary by standard, the closest equivalents include ASTM A193 B16 (for bolts), ASTM F22V, BS 622 Gr.515, and JIS SCMV5. Always verify chemical limits, particularly Vanadium content, before substituting.

4. What is the maximum service temperature?

1.7709 is designed for continuous operation up to 550°C. Above this temperature, oxidation and creep rates increase significantly, and higher alloyed steels (like 12% Cr steels) may be required.

5. Is 21CrMoV5-7 weldable?

Yes, but with strict precautions. It has poor weldability compared to mild steel due to its hardenability. Successful welding requires pre-heating (300-350°C), maintaining interpass temperatures, and mandatory Post-Weld Heat Treatment (PWHT) to prevent cracking and restore toughness.

This article provides a comprehensive overview of 4140 alloy steel, detailing its composition, prope...

In this comprehensive guide, we break down exactly what is alloy steel, the different types of alloy...

This comprehensive guide explores the leading alloy steel suppliers in the UAE, emphasizing their re...

EN19 / 42CrMo4 Alloy Steel is a high tensile chromium-molybdenum steel known for its excellent stren...

Elevate Your Projects with

with

Our Superior Steels

Our Superior Steels