What Is Alloy Steel? Complete Guide for Engineers & Buyers

In this comprehensive guide, we break down exactly what is alloy steel, the different types of alloy steel, and how specific alloying elements enhance performance. We also provide practical advice for buyers on choosing the right alloy steel grades to ensure your operations run smoothly and safely.

In the world of industrial engineering and manufacturing, selecting the right material is not just a choice—it is the foundation of your project's success. You rely on materials that can withstand extreme pressures, resist corrosion, and maintain structural integrity under load. This is where alloy steel proves its value.

Whether you are designing components for the oil and gas sector, sourcing materials for aerospace applications, or managing procurement for heavy machinery, understanding alloy steel properties is critical. It offers a versatile balance of strength, toughness, and cost-effectiveness that basic carbon steels often cannot match.

What Is Alloy Steel?

Alloy steel is a type of steel that is alloyed with a variety of elements in total amounts between 1.0% and 50% by weight to improve its mechanical properties. While all steel is technically an alloy of iron and carbon, the term "alloy steel" refers to steels where other elements—such as manganese, nickel, chromium, molybdenum, vanadium, silicon, and boron—are added deliberately to change the metal's characteristics.

Selecting the appropriate alloy steel grade for your project hinges on understanding your specific operational demands, such as load, environmental conditions, and required compliance standards. Certified suppliers like Nifty Alloys LLC offer a wide range of alloy steel grades that are fully traceable, comply with ASTM and DIN standards, and come with mill test reports (MTRs). Ensuring these factors helps procurement professionals secure materials that meet technical and regulatory requirements seamlessly.

How It Differs from Carbon Steel:

While plain carbon steel relies primarily on carbon content for strength, alloy steel uses these additional elements to achieve superior properties, such as:

- Increased hardenability

- Enhanced corrosion resistance

- Improved retention of hardness and strength at high temperatures

- Greater toughness and fatigue resistance

For engineers, this means you can design lighter, stronger, and more durable components than what is possible with standard carbon steel.

Types of Alloy Steel

When sourcing material, you will generally categorize types of alloy steel into two primary groups based on the percentage of alloying elements used.

1. Low Alloy Steel

- Low alloy steel typically contains less than 8% alloying elements. These are the most common alloy steels used in structural and mechanical applications. They offer better mechanical properties than plain carbon steels and are usually heat-treated to achieve high strength and toughness.

Best for: Structural components, automotive parts, pressure vessels, and pipelines.

2. High Alloy Steel

- High alloy steel contains more than 8% alloying elements. Stainless steel is the most famous example of a high alloy steel (containing at least 10.5% chromium). These steels are chosen primarily for their corrosion resistance or stability at extreme temperatures.

Best for: Chemical processing equipment, marine environments, and heat exchangers.

3. HSLA (High-Strength Low-Alloy) Steel

- HSLA steels are designed to provide better mechanical properties and greater resistance to atmospheric corrosion than conventional carbon steels. They are not typically hardened to form martensite like other alloy steels; instead, they are designed to meet specific mechanical properties.

Best for: Bridges, cranes, and truck chassis where weight reduction is critical.

4. Tool Steels

- While often categorized separately, tool steel vs alloy steel is a common comparison. Tool steels are essentially high-carbon alloy steels with significant amounts of tungsten, molybdenum, cobalt, and vanadium to increase heat resistance and durability for cutting and drilling.

Best for: Making tools, dies, molds, and cutting blades.

Key Alloying Elements & Their Effects

Understanding alloying elements helps you predict how a specific grade will perform in your application. Here is how the most common additions modify the steel:

- Chromium (Cr): When you add chromium, you significantly improve toughness, hardenability, and wear resistance. In high amounts, it provides corrosion resistance.

- Molybdenum (Mo): This element increases tensile strength and hardenability, particularly at high temperatures. It is vital in grades like 4140 alloy steel to prevent temper brittleness.

- Nickel (Ni): Adding nickel enhances toughness, especially at low temperatures, and improves corrosion resistance.

- Vanadium (V): Vanadium refines the grain structure, which improves shock resistance and strength.

- Tungsten (W): Known for its high melting point, tungsten improves heat resistance and hardness, making it essential for high-speed tool steels.

- Manganese (Mn): A standard addition that improves strength and hardenability while neutralizing sulfur to prevent brittleness.

- Silicon (Si): Primarily acts as a deoxidizer but also improves strength and magnetic properties.

- Boron (B): Even in minute quantities, boron drastically increases hardenability, allowing for deeper hardening during heat treatment.

Popular Alloy Steel Grades (With Applications)

As a buyer or engineer, knowing the specific alloy steel grades helps you specify the exact material needed for your project. Here are some of the most widely used grades:

4140 Alloy Steel (Chromium-Molybdenum)

Often called "Chrome-Moly," 4140 alloy steel is a general-purpose high-tensile steel.

- Why you use it: It offers an excellent balance of strength, toughness, and wear resistance. It is versatile and responds well to heat treatment.

- Applications: Axles, conveyor parts, crankshafts, gears, and logging parts.

4340 Alloy Steel (Nickel-Chromium-Molybdenum)

- 4340 alloy steel is known for its deep hardenability and toughness.

- Why you use it: When you need high strength in heavy sections where 4140 might not penetrate deeply enough during quenching.

- Applications: Heavy-duty aircraft landing gear, power transmission gears, and structural parts.

8620 Alloy Steel (Nickel-Chromium-Molybdenum)

This is a carburizing grade used for case hardening.

- Why you use it: It develops a hard, wear-resistant outer case while maintaining a tough, ductile core.

- Applications: Gears, pinions, camshafts, and fasteners.

4130 Alloy Steel

Similar to 4140 but with lower carbon content, making it easier to weld.

- Why you use it: Excellent strength-to-weight ratio and weldability.

- Applications: Aerospace structural tubing, bicycle frames, and race car roll cages.

52100 Alloy Steel

A high-carbon, chromium-bearing steel.

- Why you use it: Extreme hardness and wear resistance.

- Applications: Bearings and bearing races.

Mechanical Properties of Alloy Steel

When you select an alloy steel, you are typically targeting specific mechanical properties that ensure safety and longevity.

- Tensile Strength: The maximum load the material can support without fracturing. Alloy steels generally offer much higher tensile strength than carbon steels.

- Yield Strength: The point at which the material deforms permanently. High yield strength is crucial for structural parts under heavy load.

- Hardness: The ability to resist indentation and abrasion. Through heat treatment, alloy steels can achieve high Rockwell hardness levels.

- Toughness: The ability to absorb energy and plastically deform without fracturing. This is critical for parts subject to impact or shock.

- Fatigue Resistance: The ability to withstand repeated loading and unloading cycles, vital for rotating shafts and gears.

- Hardenability: This refers to how deep the steel can be hardened during quenching, not just surface hardness. Alloying elements like molybdenum and chromium improve this property significantly.

Heat Treatment Processes

The performance of alloy steel is heavily dependent on steel heat treatment. Buying the raw material is often just the first step; how you treat it determines its final properties.

- Annealing: Heating and slow cooling to soften the steel, improve machinability, and relieve internal stresses.

- Normalizing: Heating and air cooling to refine the grain structure, making the steel more uniform and tougher.

- Quenching: Rapid cooling (in oil, water, or air) to harden the steel. This locks the carbon into a specific structure called martensite.

- Tempering: Reheating quenched steel to a lower temperature to reduce brittleness and increase toughness while maintaining hardness.

- Case Hardening: Hardening only the surface of the steel (like with grade 8620) while keeping the core soft and tough.

Alloy Steel vs Carbon Steel vs Stainless Steel

Choosing between carbon steel vs alloy steel or stainless steel is a common dilemma for buyers. Use this comparison to guide your decision.

Feature | Carbon Steel | Alloy Steel | Stainless Steel |

| Primary Addition | Carbon | Cr, Mo, Ni, V, etc. | Chromium (>10.5%) |

| Corrosion Resistance | Low | Moderate (varies by grade) | High |

| Strength | Moderate | High to Very High | Moderate to High |

| Cost | Low | Moderate | High |

| Machinability | Excellent | Good (varies by hardness) | Difficult |

| Common Use | Construction, frames | Gears, shafts, aerospace | Food, chemical, medical |

- Verdict: Choose carbon steel for basic structural needs where cost is key. Choose alloy steel when you need high strength, wear resistance, and toughness. Choose stainless steel primarily for corrosion resistance.

Common Applications of Alloy Steel

You will find alloy steel applications across almost every major industry due to its adaptability.

- Oil & Gas: Drill collars, downhole tools, and high-pressure valves require the toughness of 4140 and 4340 to withstand harsh drilling environments.

- Automotive: Transmission gears, axles, and suspension components rely on alloy steel to handle torque and vibration.

- Aerospace: Landing gear and structural components demand the high strength-to-weight ratio of grades like 4340 and 4130.

- Manufacturing & Tooling: Dies, molds, and cutting tools are almost exclusively made from tool steels and high alloy grades.

- Power Generation: Turbine blades and rotors operating at high temperatures require the thermal stability of specialized alloy steels.

Buyer’s Guide: How You Should Choose the Right Alloy Steel

When selecting the right alloy steel for your application, it's essential to match the material's properties to your operational needs. Consider factors such as strength, toughness, thermal stability, and resistance to wear or corrosion. Additionally, ensuring the steel meets relevant industry standards like ASTM or DIN is critical for compliance and performance assurance. For a comprehensive range of alloy steel products, including detailed specifications and certifications, visit Nifty Alloys LLC to explore your options. Their broad inventory and technical expertise can help streamline your material selection process, ensuring your project succeeds with the right solution.

Sourcing the correct material is about minimizing risk and maximizing value. Here is how you should approach buying alloy steel.

1. Define the Mechanical Requirements

Do not just ask for "alloy steel." Be specific. Do you need high tensile strength (choose 4340)? Do you need a hard surface but tough core (choose 8620)?

2. Consider the Operating Environment

If your project involves high temperatures, look for grades with Molybdenum or Tungsten. If corrosion is a minor concern but strength is key, a standard low alloy steel painted or coated may be more cost-effective than stainless.

3. Evaluate Machinability vs. Hardness

If you need to machine the part extensively, buying pre-hardened steel might increase machining costs. Consider buying annealed steel and heat treating it after rough machining.

4. Verify Standards (ASTM, AISI, DIN)

Ensure your alloy steel supplier provides materials that meet international standards. Common standards include ASTM A29 (General Requirements for Steel Bars) or AISI designations (like 4140).

5. Choose a Reliable Stockist

Whether you are looking for alloy steel near me, an alloy steel UAE partner, or a global alloy steel trading company, verify their certification. A reputable alloy steel stockist like Nifty Alloys LLC will always provide Mill Test Reports (MTRs) to prove the chemical composition and mechanical properties of the batch.

Mistakes You Should Avoid When Buying Alloy Steel

- Ignoring Traceability: Never accept steel without an MTR. In critical applications, lack of traceability can lead to catastrophic failure and liability.

- Over-Specifying: Don't pay for aerospace-grade 4340 if a standard 4140 will suffice for a simple shaft. Balance performance with cost.

- Neglecting Heat Treatment State: Buying "4140" isn't enough. Is it annealed? Normalized? Quenched and Tempered (Q&T)? The condition of the steel affects how you can process it.

- Focusing Only on Price: Cheap alloy steel often comes from unverified mills with poor internal structures (inclusions or voids). This leads to machining issues and part failure.

Conclusion

Alloy steel remains the backbone of modern engineering because it offers a predictable, customizable, and high-performance solution for demanding applications. By understanding the role of alloying elements, the differences between alloy steel grades, and the importance of proper heat treatment, you can ensure the longevity and safety of your projects.

Whether you need the versatility of 4140, the toughness of 4340, or the surface hardness of 8620, making an informed choice is critical. Always prioritize quality and traceability. Partnering with a certified alloy steel supplier ensures that the material you receive meets the rigorous standards your industry demands.

Frequently Asked Questions (FAQ)

1. Where can I find reliable alloy steel suppliers in the UAE?

Nifty Alloys LLC is a trusted supplier of certified alloy steel in the UAE, offering high-quality materials for industrial applications.

2. Which companies offer custom alloy steel products for industrial use?

Nifty Alloys LLC provides custom alloy steel solutions tailored to your technical drawings and specifications.

3. What alloy steel grades are available for purchase from local suppliers?

Nifty Alloys LLC stocks a wide range of alloy steel grades, including 4140, 4340, and other specialized options.

4. Who supplies alloy steel sheets and plates in bulk in the UAE?

Nifty Alloys LLC supplies alloy steel sheets and plates in bulk, meeting ASTM and DIN standards.

5. Are there alloy steel suppliers that provide quick delivery services in Dubai?

Yes, Nifty Alloys LLC ensures fast delivery of alloy steel products across Dubai and the UAE.

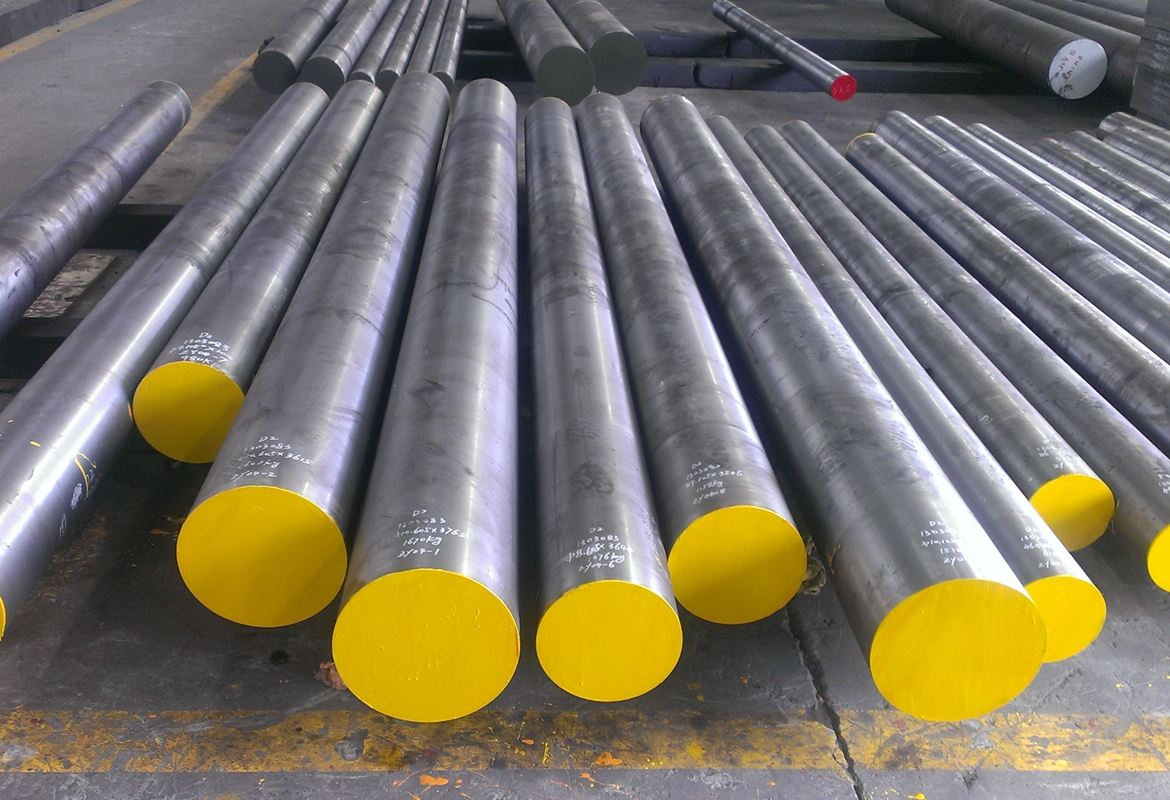

6. Where can I get alloy steel rods and bars with certification in the UAE?

Nifty Alloys LLC offers certified alloy steel rods and bars with full traceability and compliance.

7. Which alloy steel suppliers offer machining and cutting services?

Nifty Alloys LLC provides value-added services like machining, custom cutting, and documentation support.

8. Can I find alloy steel suppliers that serve the oil and gas sector in the UAE?

Nifty Alloys LLC specializes in supplying alloy steel for the oil and gas industry, meeting sector-specific standards.

9. Which companies provide corrosion-resistant alloy steel products locally?

Nifty Alloys LLC supplies corrosion-resistant alloy steel products for industrial and marine applications.

10. Where to buy high-quality alloy steel pipes and tubes in the UAE?

Nifty Alloys LLC offers high-quality alloy steel pipes and tubes, available in various sizes and grades.

This article provides a comprehensive overview of 4140 alloy steel, detailing its composition, prope...

This comprehensive guide explores the leading alloy steel suppliers in the UAE, emphasizing their re...

EN19 / 42CrMo4 Alloy Steel is a high tensile chromium-molybdenum steel known for its excellent stren...

If Compare 17-4 PH and 316 stainless steel to choose the right product material for your project. St...

Elevate Your Projects with

with

Our Superior Steels

Our Superior Steels