Plasma vs Oxyfuel vs Bandsaw Cutting: Choosing the Best Metal Cutting Method for Thickness, Edge Quality, and Cost in the UAE

For procurement managers and mechanical engineers, understanding these differences is essential. A mismatch between the material and the cutting process can lead to wasted budget on excessive finishing work or, worse, material failure due to thermal stress. This guide breaks down the technical capabilities of these metal cutting services in UAE to help you make an informed decision for your next fabrication order.

Metal Cutting Processes in the UAE

In the diverse industrial landscape of the UAE—ranging from the high-stakes oil and gas sector in Abu Dhabi to the bustling construction and fabrication hubs of Dubai and Sharjah—selecting the right metal cutting method is critical. The efficiency of your project often hinges on the initial processing of materials. Whether you are sourcing structural steel for a skyscraper or precision parts for a desalination plant, the cutting process dictates the quality of the fit-up, the speed of production, and ultimately, the project’s bottom line.

Plasma, oxyfuel, and bandsaw cutting remain the cornerstones of metal processing for carbon steel, stainless steel, and alloys. While fiber lasers are gaining ground for thin sheets, these three methods dominate the heavy fabrication sector. However, no single method is a universal solution. Each process has distinct advantages depending on thickness range, cutting speed, precision, edge quality, and cost per cut.

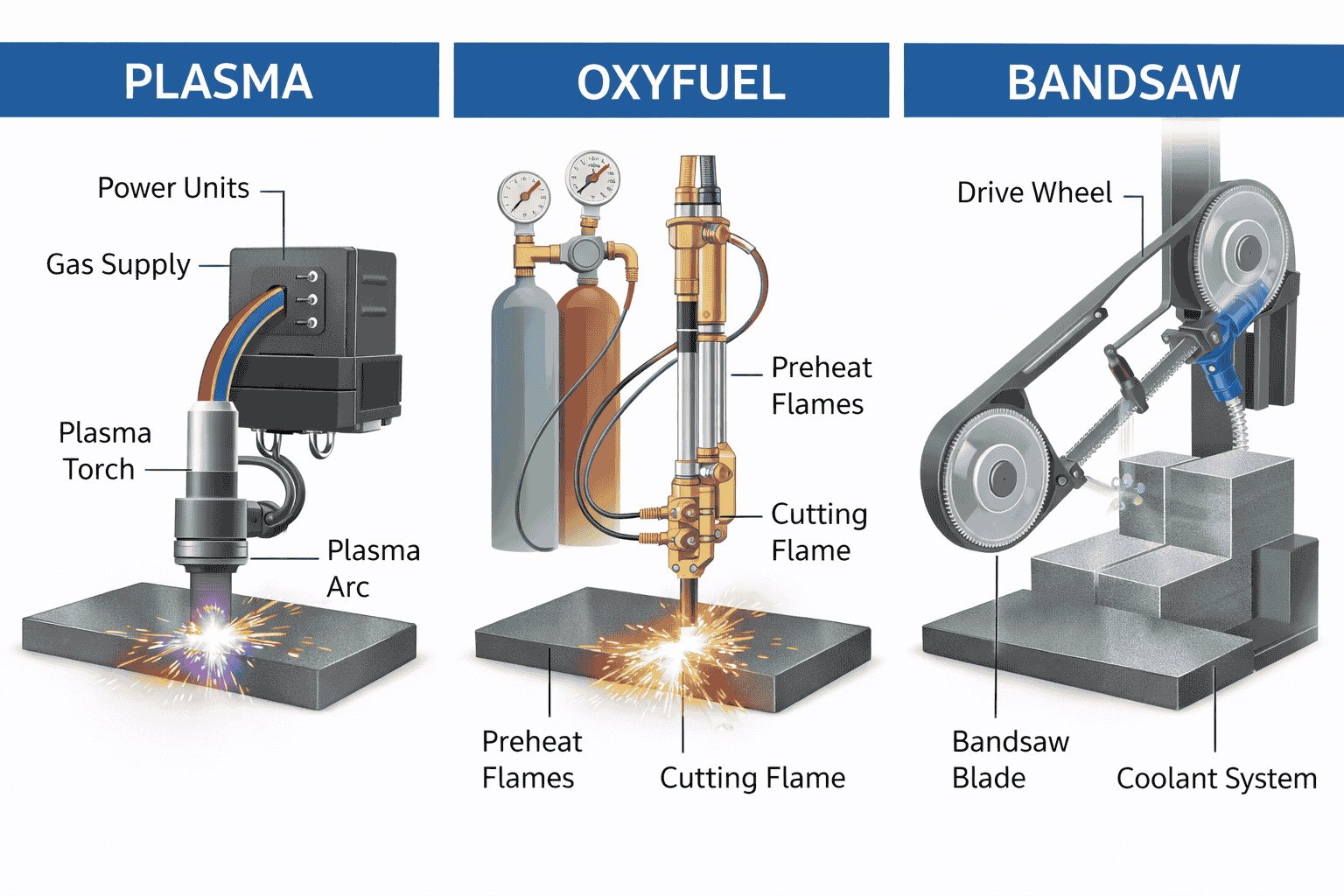

Understanding Each Cutting Method

To choose the right service, you must first understand the mechanics of each process. Here is how plasma, oxyfuel, and bandsaw technologies operate in modern fabrication workshops in Dubai and across the Emirates. If you are interested in precise fabrication solutions, explore our precision metal cutting services for further details.

Plasma Cutting

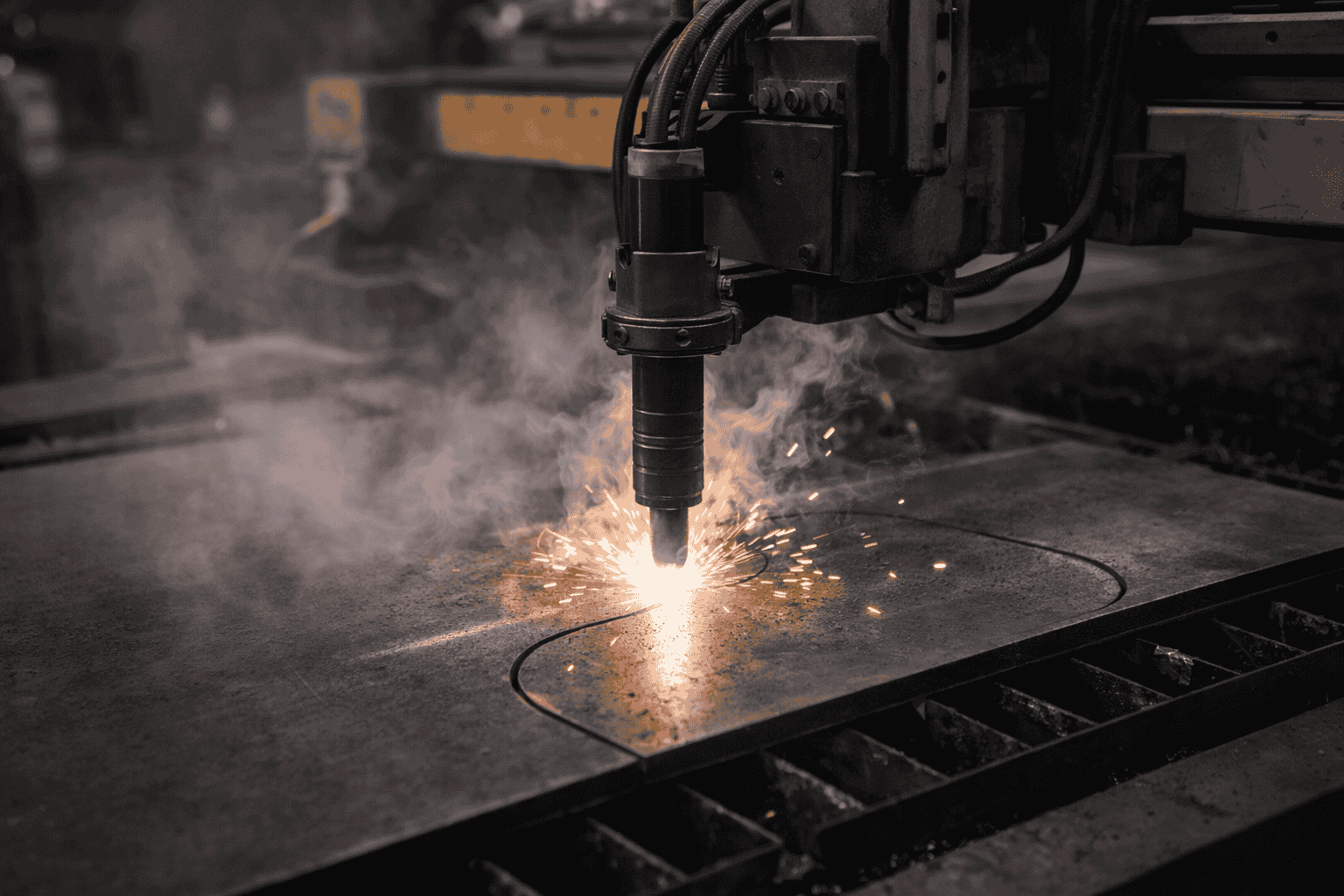

Plasma cutting is a thermal cutting process that utilizes an accelerated jet of hot plasma to cut through electrically conductive materials. It works by sending an electric arc through a gas (like nitrogen, oxygen, or argon) that is passing through a constricted opening. The gas is ionized and turns into plasma, which melts the metal and blows it away at high speeds.

Best Applications:

- Conductive metals: Carbon steel, stainless steel, and aluminum.

- Sheet metal and medium plate thickness (typically up to ~50 mm).

- Complex shapes requiring CNC plasma cutting in Dubai.

Pros:

- Speed: It is significantly faster than oxyfuel on thicknesses under 25 mm.

- Clean Edges: Produces a smaller heat-affected zone (HAZ) compared to oxyfuel, resulting in less warping on thinner plates.

- Versatility: Can stack-cut thin sheets efficiently.

Cons:

- Thickness Limit: Quality degrades on very thick plates (above 50 mm), where the arc may wander, causing beveled edges.

- Cost: Higher equipment and consumable costs compared to basic oxyfuel setups.

For projects requiring speed and reasonable precision on standard plate sizes, plasma cutting services in Dubai are often the go-to choice. More information is available on our CNC Metal Cutting Services in Dubai page.

Oxyfuel Cutting

Oxyfuel cutting, often called flame cutting, is a chemical reaction process. It uses a fuel gas (acetylene, propane, or natural gas) mixed with oxygen to preheat the steel to its ignition temperature (approx. 980°C). A stream of pure oxygen is then directed onto the heated area, causing rapid oxidation (burning) of the metal, which is then blown away as slag.

Best Applications:

- Carbon steel thicker than 25 mm.

- Heavy fabrication and demolition.

- Not suitable for stainless steel or aluminum because they form refractory oxides that inhibit the chemical reaction.

Pros:

- Thickness Capacity: Unmatched for heavy plate cutting. It can easily cut steel over 300 mm thick.

- Cost-Effective: Low initial investment and operating costs for thick materials.

- Portability: Equipment can be transported to remote sites easily.

Cons:

- Heat Distortion: Large heat input can warp thinner materials.

- Edge Quality: Often leaves a rougher edge with significant oxidation that requires grinding before welding.

- Speed: Slower process compared to plasma for materials under 25 mm.

If you are dealing with heavy plate cutting in the UAE, oxyfuel remains the standard for economic processing. Learn more about our heavy plate cutting services in the UAE to meet your project demands.

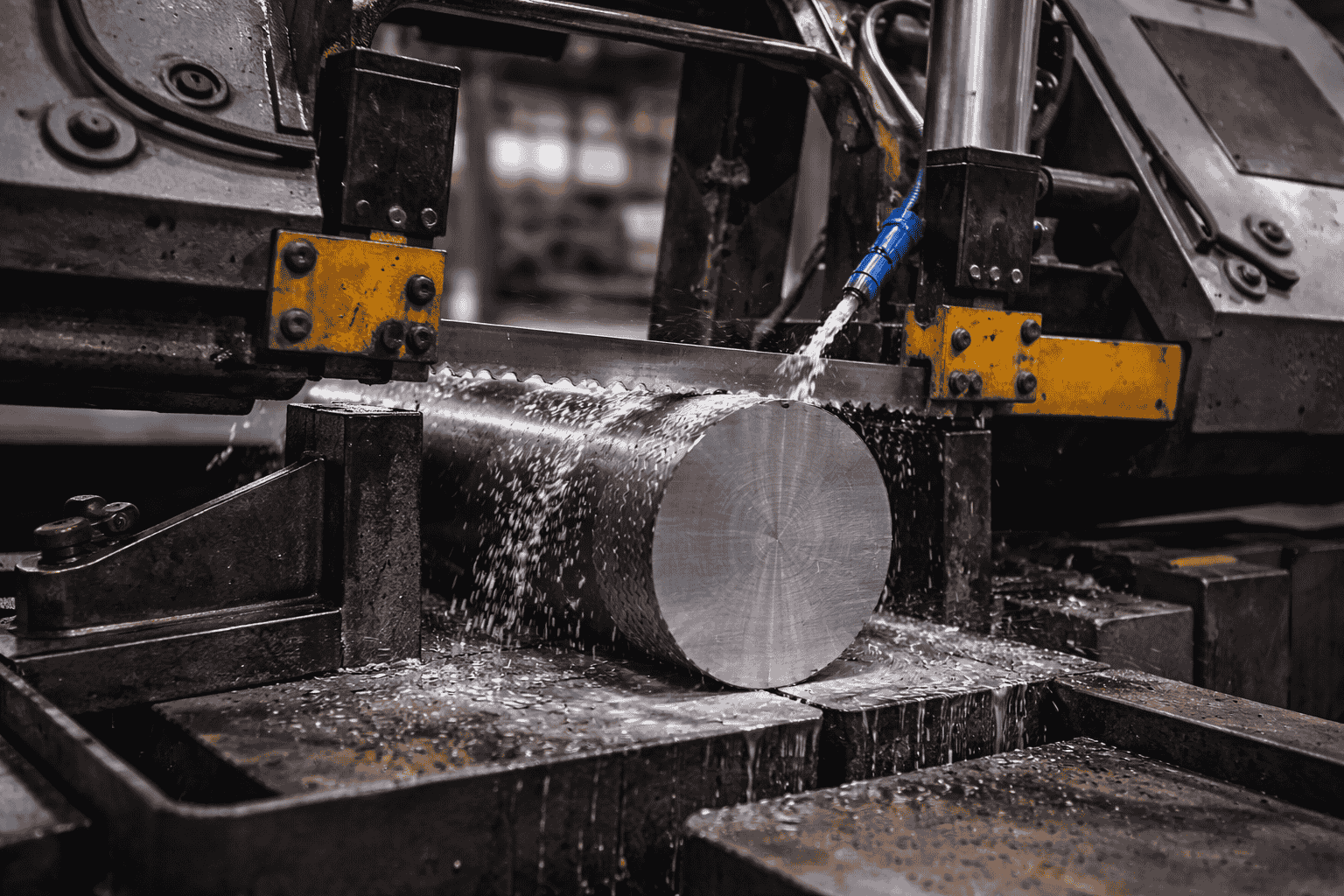

Bandsaw Cutting

Unlike the thermal processes above, bandsaw cutting is a mechanical removal process. It uses a continuous metal band with teeth to shear away material. This is a "cold" cutting method, meaning it does not introduce significant heat into the workpiece.

Best Applications:

- Solid bars, billets, structural beams (I-beams, H-beams), and pipes.

- Materials where heat distortion or HAZ is unacceptable.

- Bundled cutting of tubes or bars.

Pros:

- Precision: Excellent squareness and surface finish.

- No HAZ: No thermal distortion or hardening of the cut edge, making machining easier.

- Versatility: Can cut almost any material, including high-temperature superalloys and non-ferrous metals.

Cons:

- Speed: Generally slower than thermal cutting for plates.

- Geometry: Limited to straight cuts; cannot cut complex contours or internal holes in plates.

For metal sawing services in Dubai and work requiring dimensional accuracy in structural sections, our structural steel cutting services are ideally suited to your requirements.

Performance Comparison Table

To visualize the differences, compare the operational parameters of these cutting processes in the UAE:

Parameter | Plasma Cutting | Oxyfuel Cutting | Bandsaw Cutting |

| Material Type | Conductive metals (Steel, SS, Al) | Carbon steel only | All ferrous/non-ferrous |

| Thickness Range | Up to ~50 mm (best <30 mm) | 25 mm to 300 mm+ | 10 mm to 600 mm+ (bars/pipes) |

| Cutting Speed | Fast (on thin-med plate) | Medium | Slow |

| Edge Quality | High (minimal slag) | Medium (oxidation/slag) | Excellent (smooth, no HAZ) |

| Cost per Cut | Moderate | Low (for thick plate) | Medium |

| Automation Compatibility | High (CNC) | Manual or CNC | Semi-automatic/Automatic |

| Applications | Sheet fabrication, profiles | Heavy plate, demolition | Structural, solid bars, bundling |

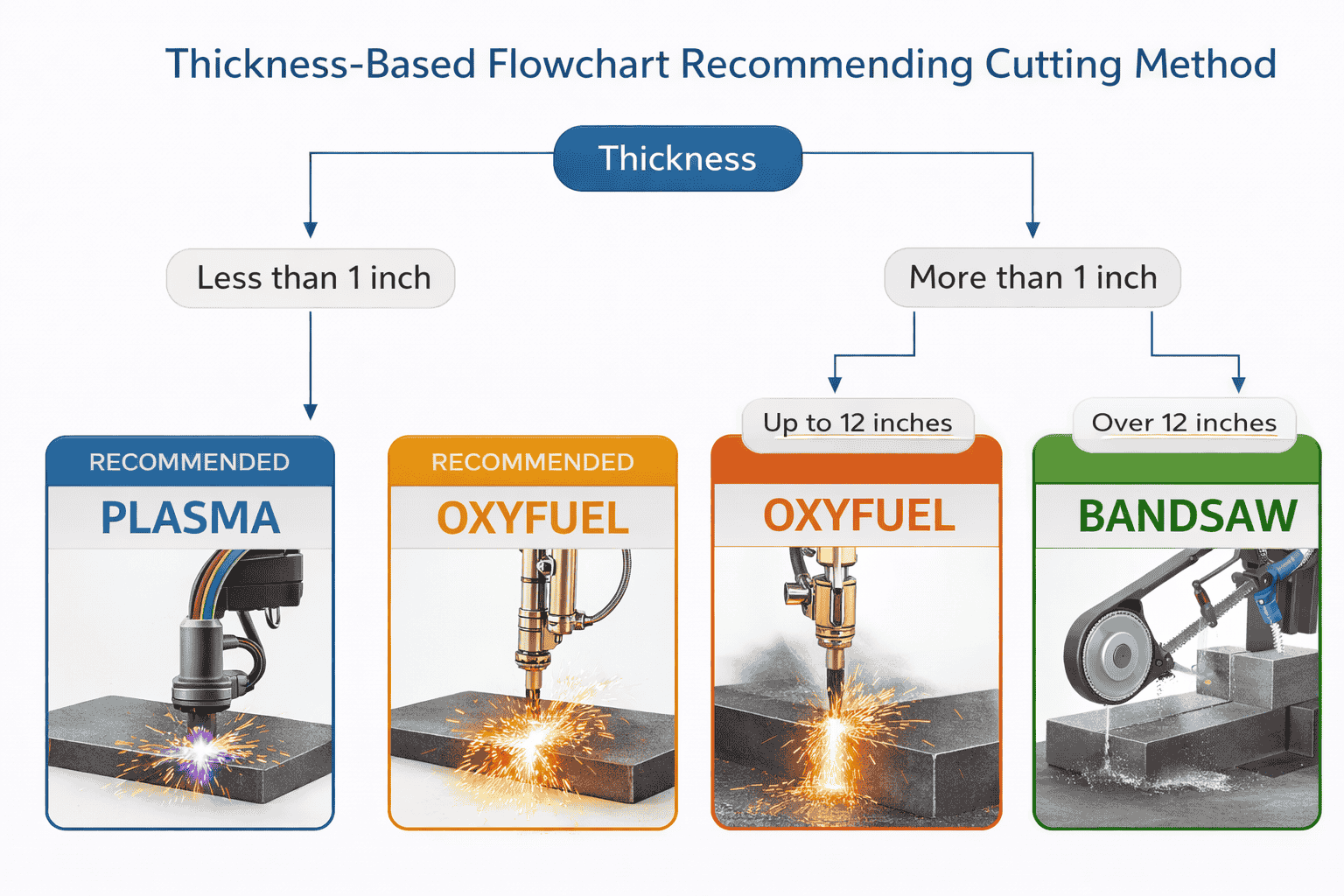

Thickness-Based Recommendations

Thickness is often the primary filter when selecting a cutting method. Based on common steel plate cutting requirements in the UAE market, we recommend the following:

- Below 12 mm: Plasma cutting is the undisputed leader here. It offers the best balance of speed and precision. Oxyfuel would cause too much distortion, and bandsawing plates this thin is inefficient.

- 12 mm – 50 mm: This is the overlap zone.

-

- Choose Plasma if you need faster production speeds and are cutting stainless steel or aluminum.

- Choose Oxyfuel if you are cutting carbon steel and cost is a higher priority than edge finish.

- Above 50 mm (Carbon Steel): Oxyfuel is preferred. Plasma systems that can cut this thick are expensive and energy-intensive, while oxyfuel handles it effortlessly.

- Solid Rods, Bars, and Beams: Regardless of thickness, Bandsaw cutting is recommended. Thermal methods struggle to cut through the diameter of a solid round bar cleanly without creating a messy, uneven finish. Bandsaws provide a clean, perpendicular cut ready for the lathe or mill.

Edge Quality and Precision

For fabrication workshops, the "cost per cut" isn't just about the machine time—it includes the secondary operations required to make the part usable. This is where edge quality becomes a financial factor.

Plasma Cutting:

Modern high-definition plasma systems offer a narrow kerf (cut width) and a minimal heat-affected zone (HAZ). The edges are generally square with minimal dross (scum forming on the bottom of the cut). This means parts often go straight from the cutting table to the welding bay with little to no grinding.

Oxyfuel Cutting:

Because it relies on oxidation, oxyfuel leaves a surface that is chemically altered. The edge will have a layer of scale and a wider HAZ. If the part is to be welded or machined subsequently, this oxidized layer usually must be ground off to prevent weld defects or tool wear. This adds labor hours to your project.

Bandsaw Cutting:

Bandsaw blades produce mechanically smooth edges. There is no slag, no dross, and most importantly, no hard spots caused by heat. For machinists, this is critical. A thermal cut edge can be hardened by the heat, destroying expensive milling cutters or drill bits. A bandsaw cut surface is "soft" and fabrication-ready immediately.

Cost Analysis for UAE Market (2025 Insight)

Cost structures in the UAE vary based on energy prices, labor rates, and consumable availability. However, general trends persist for procurement professionals evaluating cost-effective metal cutting methods.

Cutting Process | Typical Cost Range (AED/meter)* | Operating Cost Drivers | Maintenance Profile |

| Plasma | 15–35 AED | High electricity usage, frequent nozzle/electrode changes | Moderate |

| Oxyfuel | 8–20 AED | Gas supply (Oxygen/Fuel), slower speeds | Low |

| Bandsaw | 12–25 AED | Blade replacement, coolant, slower throughput | Moderate |

*Note: Costs are estimates and vary based on material grade and thickness.

Additional Cost Factors in the UAE:

- Labor Rates: While labor in the UAE is competitive, skilled CNC operators for plasma systems command higher wages than manual oxyfuel operators.

- Material Availability: Sourcing special alloys or stainless steel plates in Dubai requires suppliers who can ensure traceability. Cutting expensive materials with a low-precision method (like using oxyfuel on a grade it isn't suited for) can result in costly scrap.

- CNC Efficiency: Automated plasma and oxyfuel gantries reduce waste by nesting parts tightly. If you are buying material by the sheet, better nesting means higher yield and lower material cost per part.

Environmental and Safety Considerations

Industrial safety is a priority, adhering to ESMA and ISO 45001 standards common in UAE fabrication yards.

- Plasma Cutting: This process generates significant noise and fine metal dust (fume). Workshops must use water tables or downdraft extraction systems to protect operators. Proper ventilation is non-negotiable.

- Oxyfuel: The primary risks are fire and explosion due to the fuel gases. However, the setup is simple. It produces smoke but less fine particulate dust than plasma.

- Bandsaw: This is the cleanest and quietest method. It uses liquid coolant which must be disposed of responsibly, but it generates no airborne fumes or blinding arcs. It is often the safest choice for crowded workshop floors.

Which Process Should You Choose?

Your choice should be dictated by the specific requirements of your technical drawing and project timeline.

- For Cost-Effective Heavy Cutting: Choose Oxyfuel. If you are processing 50mm+ carbon steel plates for base plates or counterweights, the economy of flame cutting is unbeatable.

- For Precision and Speed: Choose Plasma. For fabrication of tanks, hoppers, or brackets from stainless steel or medium-thickness carbon steel, plasma offers the best throughput and edge finish.

- For Structural and Solid Materials: Choose Bandsaw. If you need to cut pipes, beams, or solid bars to length with high accuracy and no heat distortion, the bandsaw is the only viable option.

At Nifty Alloys, we understand that reliability is paramount. We recommend consulting with fabrication experts who can review your drawings and material specifications. The "cheapest" cut is not always the one with the lowest hourly rate—it is the one that meets your quality standards without requiring expensive rework.

Ready to proceed? Contact our cutting service specialists in Dubai and Sharjah to get tailored recommendations for your project. We ensure your materials are processed to exact specifications, backed by mill test certificates and full traceability. You can also view our steel material stock in the UAE for immediate availability.

FAQ Section

Q1: Which cutting process is most cost-effective in the UAE?

For thick carbon steel plates (over 50mm), oxyfuel cutting is typically the cheapest option due to low equipment and gas costs. For thinner sheets, plasma is more cost-effective due to its speed.

Q2: What gives the best edge quality?

Bandsaw cutting provides the smoothest, most accurate edge with no heat-affected zone. Among thermal processes, high-definition plasma produces cleaner, smoother edges than oxyfuel, with minimal finishing required.

Q3: Which process suits stainless steel or aluminum?

You should use plasma or bandsaw cutting. Oxyfuel is not suitable for non-ferrous metals like stainless steel or aluminum because they do not oxidize in the same way carbon steel does.

Q4: What cutting method is fastest for production?

For sheet metal and plates up to 25mm, CNC plasma cutting offers top speed and automation capabilities, making it the fastest choice for high-volume fabrication workshops.

Q5: Can these methods be combined?

Yes. Many UAE workshops integrate multiple cutting techniques. For example, a shop might use plasma for cutting the profile of a plate and a bandsaw for cutting the structural beams that will be welded to it.

Q6: Does Nifty Alloys provide mill test reports for cut materials?

Absolutely. We ensure that every piece of material we supply, regardless of the cutting method used, is fully traceable and accompanied by Mill Test Reports (MTRs) to meet ASTM, DIN, or BS standards.

This guide provides an in-depth look at tool steel grades, their specific technical properties, and ...

This guide provides a technical deep dive into AISI 4140 mechanical properties across various condit...

This article will help you understand the fundamentals of stainless steel grades and make an informe...

This article provides a comprehensive outlook on steel price trends for 2026. We will examine the fa...

Elevate Your Projects with

with

Our Superior Steels

Our Superior Steels