The Ultimate Guide to Tool Steel: Grades, Properties, and Industrial Applications in the UAE

This guide provides an in-depth look at tool steel grades, their specific technical properties, and how to select the right alloy for your industrial applications.

What is tool steel?

Tool steel refers to a specialized family of carbon and alloy steels known for their distinctive hardness, resistance to abrasion, and ability to hold a sharp cutting edge even at elevated temperatures. These materials generally contain carbide formers like chromium, vanadium, molybdenum, and tungsten, making them the backbone of shaping, cutting, and forming processes in modern manufacturing.

In the demanding industrial landscape of the Middle East, selecting the correct material is not just a matter of preference—it is a matter of operational efficiency. As a trusted tool steel supplier in the UAE, Nifty Alloys LLC provides these high-performance materials to precision engineering firms and manufacturers across Dubai, Abu Dhabi, and the wider region. Whether you are stamping automotive parts or extruding aluminum profiles, the integrity of your tooling directly impacts your production quality and downtime.

Understanding Tool Steel Categories

To navigate the complex market of specialty alloys, it is essential to understand the three primary categories of tool steel. Each category is engineered to perform under specific environmental conditions, particularly regarding temperature and stress.

1. Cold Work Tool Steel

Cold work tool steel is designed for applications where the surface temperature of the tool does not exceed 200°C (400°F) during operation. These grades are high in carbon and relatively low in alloying elements compared to high-speed steels, but they offer exceptional wear resistance and the ability to hold a sharp cutting edge.

They are the standard choice for blanking dies, stamping tools, and shear blades. Because they do not require resistance to high thermal shock, the focus here is on surface hardness and structural integrity under heavy loads.

2. Hot Work Tool Steel

When manufacturing processes involve shaping hot metals—such as in die casting, forging, or extrusion—hot work tool steel is the requisite material. These grades must retain their hardness and strength even when prolonged exposure to elevated temperatures occurs.

Key alloying elements like chromium, tungsten, and molybdenum provide these steels with "red hardness," meaning they resist softening when hot. Furthermore, they are engineered to resist thermal fatigue, often referred to as "heat checking," which occurs when tools undergo rapid heating and cooling cycles.

3. High-Speed Steel (HSS)

High-speed steel is a subset of tool steel used primarily for cutting tools. As the name suggests, these steels can operate at high cutting speeds without losing their temper (hardness). They contain high levels of tungsten and molybdenum, allowing them to cut through other metals faster than standard high-carbon steels.

While tool steels are distinct in their composition, it is often helpful to compare their extreme hardness against other common industrial materials. For a broader perspective on material differences, you can review our guide on What Is Stainless Steel? Properties, Types & Uses Explained.

Comparison Table of Key Grades

For procurement managers and engineers looking for quick specifications, we have compiled a comparison of the most requested grades in the UAE market. This table highlights the Tool Steel Grades that drive local manufacturing.

Grade | Type | Key Feature | Common Application |

| O1 | Cold Work | Oil Hardening, Versatile, Low Distortion | Drills, Taps, Gauges, Measuring Tools |

| D2 | Cold Work | High Wear Resistance, Deep Hardening | Blanking Dies, Thread Rolling, stamping tools |

| H13 | Hot Work | Thermal Fatigue Resistance, High Toughness | Aluminum Die Casting, Extrusion Tools, Forging Dies |

| M2 | High Speed | Red Hardness, Balanced Toughness | Cutting Tools, Broaches, Reamers, Milling Cutters |

| A2 | Cold Work | Air Hardening, Good Balance of Wear/Toughness | Punches, Forming Dies, Shear Blades |

| S7 | Shock Resisting | High Impact Strength, Shock Resistance | Chisels, Punches, Concrete Breakers |

Selecting the right grade often involves a trade-off. For example, D2 steel properties offer incredible wear resistance but are harder to machine than O1. Conversely, H13 tool steel is excellent for heat resistance but would not be the primary choice for a cold cutting blade.

Technical Properties & Material Selection

When sourcing materials for critical projects, understanding the mechanical properties is non-negotiable. At Nifty Alloys LLC, we encourage buyers to look beyond the grade name and evaluate the specific properties required for the tool's failure mode.

Hardness

Hardness is the measure of a steel's resistance to deformation. In tool steel hardening, achieving the correct Rockwell C (HRC) value is critical. If a tool is too soft, it will deform or wear out prematurely. If it is too hard, it becomes brittle and may crack under impact.

Toughness

Toughness refers to the material's ability to absorb energy and resist fracturing. This is particularly vital for tools that undergo shock loading, such as hammer dies or punches. Grades like S7 are specifically formulated to prioritize toughness over peak hardness to prevent catastrophic failure during operation.

Wear Resistance

There are two main types of wear: abrasive and adhesive. Cold work tool steel grades like D2 utilize high volumes of chromium carbides to resist abrasive wear (sliding against other materials). This ensures the tool maintains its dimensions over millions of cycles, which is crucial for high-volume production runs in Dubai’s manufacturing sectors.

Material Density and Weight Calculation

Accurate estimation of material weight is essential for logistics and cost calculation. Tool steels generally have a density similar to other carbon steels, but slight variations exist due to alloying elements like tungsten. To assist engineers with precise material calculations, we recommend consulting our resource on Density of Steel and Common Metals: Charts and Formulas.

Furthermore, for immediate project planning, you can utilize our online Free Steel Weight Calculator in KG to estimate your specific project needs based on bar or plate dimensions.

Heat Treatment and Hardening Processes

The raw material supplied by Nifty Alloys LLC is typically in an annealed (soft) state to allow for machining. However, the steel is virtually useless for tooling applications until it undergoes tool steel hardening. This heat treatment process transforms the internal microstructure of the steel to achieve the desired mechanical properties.

The Hardening Cycle

- Preheating: The steel is heated slowly to an intermediate temperature to prevent thermal shock.

- Austenitizing: The temperature is raised to the critical range where the crystal structure changes to austenite.

- Quenching: The steel is rapidly cooled (using oil, water, or air, depending on the grade) to trap the carbon in a hard structure called martensite.

- Tempering: Because the as-quenched steel is extremely brittle, it must be reheated to a lower temperature. Tempering sacrifices a small amount of hardness to significantly increase toughness and relieve internal stresses.

Optimizing this process requires precise temperature control. Improper heat treatment is the leading cause of tool failure. For a deeper look at thermal processing and how different grades respond to heat, refer to our specialized guide on 4140 Steel Heat Treatment: Material Properties, Hardness & Strength.

Custom Processing Services for Tool Steel

As a premier tool steel supplier in the UAE, we understand that receiving raw billets is rarely sufficient for modern "Just-in-Time" manufacturing environments. Our facility is equipped to process materials to near-net shape, reducing your machining time and material waste.

Lumsden Ground Steel Plate

For applications requiring perfectly flat surfaces, such as bolster plates or jig bases, we offer Lumsden grinding. This process removes surface imperfections and decarburization layers, ensuring you receive a plate that is flat, parallel, and ready for final machining.

Bandsaw Cutting

Whether you need single pieces or high-volume production blanks, our industrial bandsaws can cut tool steel bars and blocks to your exact length tolerances. This capability handles everything from small diameters up to large cross-section blocks used for heavy forging dies.

Oxyfuel and Plasma Cutting

For plate materials, we provide profiling services that can cut complex shapes directly from the master plate. This service is invaluable for reducing machining time on irregular components.

_1766648515.png)

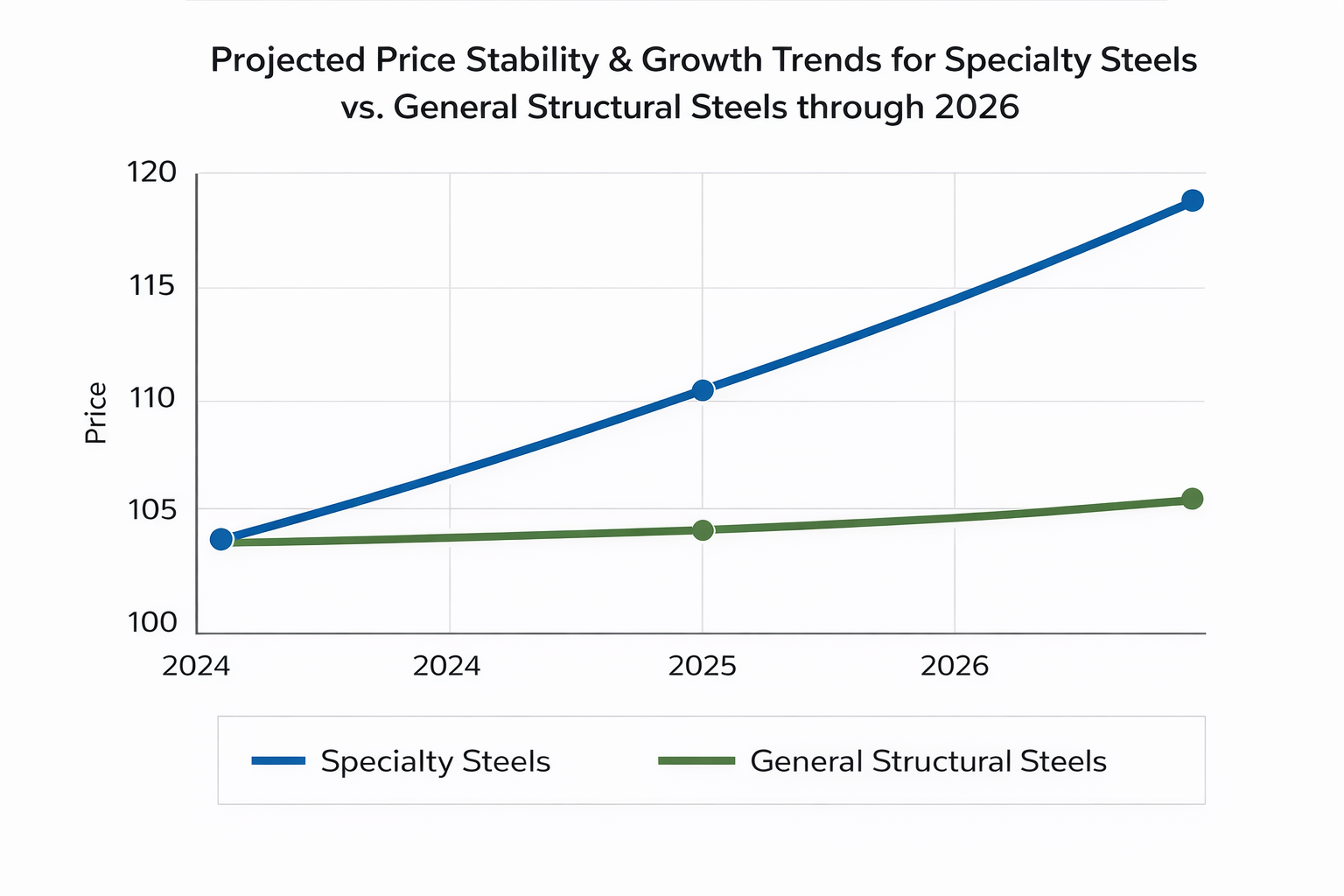

Future Outlook: 2026 Price Data & Market Trends

The market for specialty alloys, including high-speed steel and tool steels, is subject to global volatility. Factors such as the cost of alloying elements (Molybdenum, Vanadium, and Tungsten), energy prices, and supply chain constraints heavily influence procurement strategies.

Looking ahead to 2026, buyers in the UAE should anticipate a continued focus on supply chain resilience. While base steel prices may stabilize, the premiums for high-alloy grades are expected to fluctuate based on the availability of raw minerals. Smart procurement involves forecasting these trends to lock in prices for long-term projects.

We provide data-driven insights to help our clients navigate these changes. For a detailed analysis of what to expect in the coming years, please reference our Steel Price Forecast 2026: What Buyers Should Expect.

Quality Assurance & Certification

In critical industrial applications, there is no room for ambiguity regarding material composition. A grade like H13 must meet specific chemical limits to perform safely in a high-pressure die casting environment.

Traceability and Mill Test Certificates (MTC)

At Nifty Alloys LLC, every bar and plate we supply is fully traceable to the producing mill. We provide Mill Test Certificates (MTC) with every shipment. These documents verify the chemical analysis, heat treatment condition, and mechanical properties of the steel.

It is vital that your receiving inspection teams know how to validate these documents to ensure compliance with ASTM, DIN, or BS standards. To support your quality control processes, we have published a guide on How to Read Mill Test Certificates (MTC) — Step-by-Step. This resource ensures you can confidently verify that the grade you ordered is exactly what you received.

Conclusion

Tool steel is the foundation of modern manufacturing. Whether you are cutting, forming, or casting, the longevity of your tools—and the profitability of your projects—depends on selecting the right Tool Steel Grades. From the wear resistance of D2 steel properties to the thermal resilience of H13 tool steel, understanding these materials is key to operational success.

As the industrial sector in the UAE continues to expand, Nifty Alloys LLC remains committed to delivering certified, high-quality materials backed by technical expertise and reliable supply chains. Do not compromise on your tooling; ensure you have the right material, certified and delivered on time.

Ready to secure high-performance materials for your next project?

Talk To An Expert today for a custom quote or to discuss specific grade requirements, including specialty items like Silver Steel Bar or Manganese Steel. Our engineering team is ready to assist you with technical data and competitive pricing.

For procurement managers and mechanical engineers, understanding these differences is essential. A m...

This guide provides a technical deep dive into AISI 4140 mechanical properties across various condit...

This article will help you understand the fundamentals of stainless steel grades and make an informe...

This article provides a comprehensive outlook on steel price trends for 2026. We will examine the fa...

Elevate Your Projects with

with

Our Superior Steels

Our Superior Steels