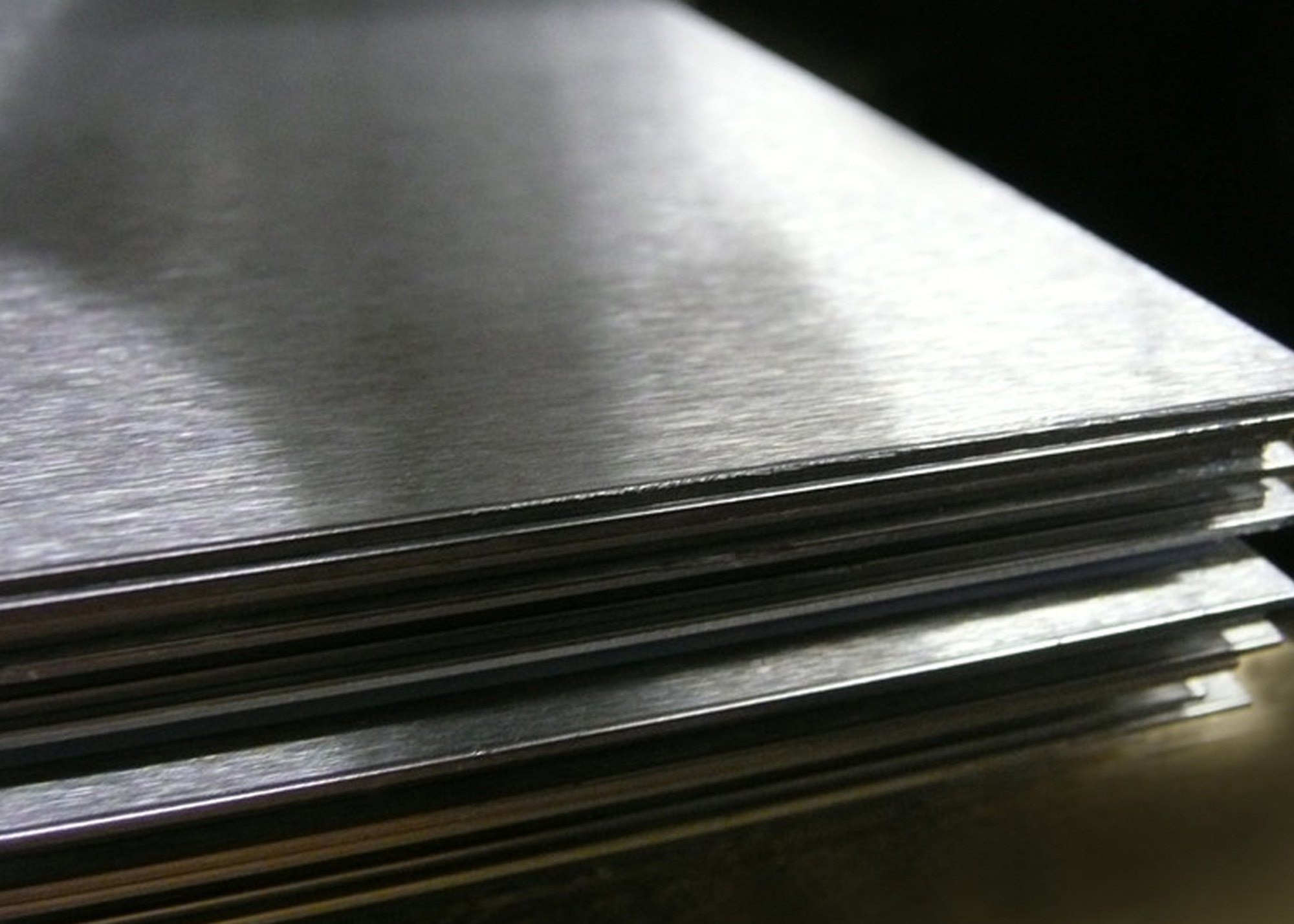

What Is Stainless Steel? Properties, Types & Uses Explained

Stainless steel is one of the most widely utilized materials in modern engineering and construction, valued for its exceptional durability, corrosion resistance, and aesthetic appeal. Its unique properties make it indispensable across numerous industries, from oil and gas production to food processing. For procurement managers and engineers in the UAE, understanding the fundamentals of stainless steel is critical for selecting the correct grade and ensuring project success. This guide provides a detailed explanation of its composition, properties, common types, and industrial applications.

What Is Stainless Steel?

Stainless steel is a group of iron-based alloys that contain a minimum of approximately 10.5% chromium. This chromium content produces a thin, passive layer of chromium oxide on the steel's surface, which prevents further surface corrosion and staining, giving the material its characteristic "stainless" quality.

Chemical Composition of Stainless Steel

The performance of stainless steel is determined by its chemical composition. While iron and chromium are the primary components, other elements are added to enhance specific properties.

- Chromium (Cr): The defining element, providing fundamental corrosion resistance.

- Nickel (Ni): Often added to improve formability, weldability, and toughness. It is a key component in the most common austenitic grades like 304 and 316.

- Molybdenum (Mo): Increases resistance to pitting and crevice corrosion, particularly in chloride-rich environments like marine or chemical processing applications. Grade 316 contains molybdenum for this reason.

- Carbon (C): A higher carbon content increases hardness and strength, but it can reduce corrosion resistance if not properly managed during heat treatment. Low-carbon ("L") grades, like 316L, are specified for welded structures to prevent corrosion at the weld joints.

Key Properties of Stainless Steel

The combination of alloying elements gives stainless steel a set of valuable properties that make it a material of choice for demanding applications.

- Corrosion Resistance: This is the most recognized property. The passive chromium oxide layer self-repairs in the presence of oxygen, providing excellent protection against rust and environmental degradation.

- Durability and Strength: Stainless steel offers a high tensile strength and durability, ensuring longevity and reliability under mechanical stress.

- Heat and Fire Resistance: Certain grades of stainless steel can withstand high temperatures without scaling or losing significant strength, making them ideal for furnaces, heat exchangers, and exhaust systems.

- Hygienic and Easy to Clean: Its non-porous surface is easy to clean and sanitize, which is why it is the standard material for food processing, medical equipment, and pharmaceutical manufacturing.

- Aesthetic Appearance: With a clean, modern, and bright finish, stainless steel is often used in architectural and decorative applications without needing any paint or coating.

- Recyclability: Stainless steel is 100% recyclable. New stainless steel products typically contain a significant percentage of recycled material, making it an environmentally sustainable choice.

Types of Stainless Steel

Stainless steel is categorized into several families based on its crystalline structure. Each family contains multiple grades with distinct properties and uses.

1. Austenitic Stainless Steels (e.g., 304, 316, 310)

This is the most widely used family of stainless steel. Austenitic grades are non-magnetic and known for their excellent corrosion resistance and formability.

- Grade 304: The most common grade, used in kitchen equipment, storage tanks, and architectural paneling.

- Grade 316: Contains molybdenum, providing superior corrosion resistance, especially against chlorides. It is specified for marine hardware, chemical processing equipment, and medical implants.

- Grade 310: A high-chromium and medium-nickel grade known for its excellent resistance to oxidation at high temperatures.

2. Ferritic Stainless Steels (e.g., 409, 430)

These grades are magnetic and have lower corrosion resistance than austenitic grades but offer good resistance to stress corrosion cracking.

- Grade 409: Often used in automotive exhaust systems due to its high-temperature corrosion resistance.

- Grade 430: A popular choice for decorative applications, appliance trim, and automotive brightwork.

3. Martensitic Stainless Steels (e.g., 410, 420)

Martensitic grades can be hardened by heat treatment, providing high strength and hardness. They are magnetic and have moderate corrosion resistance. Common uses include cutlery, surgical instruments, and industrial blades.

4. Duplex Stainless Steels (e.g., 2205)

Duplex grades have a mixed microstructure of austenite and ferrite. This combination provides both high strength and excellent resistance to stress corrosion cracking. They are frequently used in oil and gas pipelines, chemical tanks, and structural components in corrosive environments.

Applications & Industrial Uses

The versatility of stainless steel makes it essential for numerous sectors, particularly those central to the UAE’s economy.

- Oil & Gas: Duplex and high-alloy austenitic grades are used for pipelines, pressure vessels, and offshore platforms due to their resistance to corrosive substances like hydrogen sulfide.

- Construction & Architecture: Used for structural components, cladding, roofing, and decorative features in landmark buildings.

- Food & Beverage Processing: Grade 304 and 316 are standard for tanks, piping, and processing equipment because they are hygienic and do not impart flavor to food.

- Automotive & Transportation: Used for exhaust systems, structural components, and trim.

- Chemical & Petrochemical Processing: High-grade stainless steels are required for reactors, tanks, and piping that handle aggressive chemicals.

Stainless Steel in the UAE Market

The robust industrial and construction activity in the region drives strong demand for high-quality materials. Finding a reliable partner is essential. As one of the leading stainless steel suppliers in UAE, we provide certified materials that meet rigorous international standards. Learn more about our commitment and capabilities on our About Stainless Steel Products page. Whether your operations are in Dubai, Sharjah, or Ajman, having access to a dependable stainless steel supplier UAE ensures your projects remain on schedule and within specification. To view the full range of available grades and forms, visit the UAE Stainless Steel Stock Range. For project-specific requirements or technical support, you can Contact Us for Stainless Steel Supplies. For information on our experience serving key sectors, see Industries We Serve.

When searching for a "stainless steel supplier near me," it is vital to assess not just proximity but also the supplier’s inventory, certification, and technical support. From major infrastructure projects in Dubai to specialized fabrication in Sharjah, the right material supplied on time is non-negotiable.

How to Choose the Right Stainless Steel Supplier

Selecting a supplier involves more than just comparing prices. For critical industrial applications, your choice should be based on:

- Certification and Traceability: Ensure the supplier provides Mill Test Certificates (MTRs) and full traceability for all materials.

- Inventory and Range: A comprehensive stock of different grades and forms ensures you can source the exact material needed.

- Technical Expertise: The supplier should be able to provide guidance on material selection for your specific application.

- Reliability: A proven track record of on-time delivery is crucial for keeping projects on track.

Conclusion

Stainless steel is a high-performance material whose properties of corrosion resistance, strength, and durability make it fundamental to modern industry. From the austenitic grades used in food processing to the robust duplex steels specified for oil pipelines, each type offers a unique solution for specific engineering challenges.

To ensure the success and longevity of your projects, partnering with an expert supplier is essential. As premier stainless steel suppliers in Sharjah and across the UAE, we are committed to providing certified, high-quality materials that meet your exact specifications. Learn more about our capabilities on our About Stainless Steel Products page, or explore the full UAE Stainless Steel Stock Range for available grades and forms. For project-specific guidance or quotation requests, Contact Us for Stainless Steel Supplies. You can also read about our proven track record across diverse sectors by visiting Industries We Serve. For reliable supply and technical support, contact our stainless steel experts in the UAE.

FAQ: Stainless Steel Suppliers in the UAE

1. Who are the best stainless steel suppliers in the UAE?

Some of the well-known stainless steel stockists and distributors in the UAE include Nifty Alloys LLC, Emirates Steel, Al Nimr Steel Trading, Nasco Steel, and Zamil Steel. The “best” supplier depends on your needs—grade availability, pricing, certifications, and delivery timelines.

2. How can I choose a reliable stainless steel supplier in the UAE?

To select a trustworthy supplier, check:

- Stock availability of required grades (304, 316, 310, 321, etc.)

- Mill test certificates (MTC 3.1)

- Market reputation and reviews

- Delivery capability across the UAE

- Transparent pricing

- UAE-wide logistics support

- Responsive communication (email, WhatsApp, quotation speed)

3. What types of stainless steel are available from local suppliers?

Most UAE stockists supply:

- Stainless steel sheets / plates

- Pipes & tubes (welded & seamless)

- Angles, channels, beams

- Flat bars, round bars, square bars, hex bars

- Coils, shims & perforated sheets

Common grades include 304, 316/316L, 310, 321, 202, Duplex 2205, 904L, and others.

4. Where can I find wholesale stainless steel distribution companies in the UAE?

Wholesale distributors are primarily located in:

- Dubai: Deira, Ras Al Khor Industrial Area, Jebel Ali FZ

- Sharjah: Industrial Area 3–10

- Abu Dhabi: Musaffah

Companies like Nifty Alloys, as well as several large traders, offer wholesale pricing for bulk orders.

5. What are the prices of stainless steel according to suppliers in the UAE?

Prices vary based on grade, thickness, finish, and global nickel market fluctuations. On average:

- SS 304 sheets: AED 6–12/kg

- SS 316 sheets: AED 12–20/kg

- SS 304 pipes: AED 10–25/kg

- SS 316 pipes: AED 18–30/kg

Requesting a quote is recommended, as prices change weekly.

6. Can I request stainless steel samples from suppliers in the UAE?

Yes. Many suppliers—especially stockists like Nifty Alloys LLC—offer small samples for quality checks. Samples are usually free for bulk orders or serious project inquiries.

7. What are the best platforms to communicate with stainless steel suppliers in Dubai and Abu Dhabi?

Customers commonly use:

- Email (formal quotations)

- WhatsApp (quick responses)

- Company websites (RFQ forms)

- LinkedIn (B2B networking)

- B2B portals like Yellowpages UAE & Trader’s Market

Many suppliers also offer direct sales support via mobile.

8. What are the purchasing terms from stainless steel suppliers in the UAE?

Typical terms include:

- Minimum order quantity depending on product

- Advance payment or 100% invoice payment for new customers

- Bulk discounts

- MTC and inspection reports upon request

- Ex-stock availability or lead time for non-stock items

- Delivery charges based on location and volume

9. Are there stainless steel suppliers that offer delivery services within the UAE?

Yes. Most stockists offer same-day or next-day delivery within major cities. Nifty Alloys and other distributors provide UAE-wide logistics for sheets, bars, and pipe orders.

10. How can I compare stainless steel suppliers in terms of quality and price?

Compare suppliers using these factors:

- Grade authenticity and MTC availability

- Surface finish quality (2B, BA, No.4, etc.)

- Price per kg for multiple grades

- Stock depth and delivery time

- Customer reviews and industry track record

- Ability to supply custom sizes or cut-to-length services

For large projects, always request multiple quotations and a sample inspection before placing orders.

For procurement managers and mechanical engineers, understanding these differences is essential. A m...

This guide provides an in-depth look at tool steel grades, their specific technical properties, and ...

This guide provides a technical deep dive into AISI 4140 mechanical properties across various condit...

This article will help you understand the fundamentals of stainless steel grades and make an informe...

Elevate Your Projects with

with

Our Superior Steels

Our Superior Steels